Sign up to receive latest insights & updates in technology, AI & data analytics, data science, & innovations from Polestar Analytics.

Editor's Note: As enterprises have grown by M&A, they are facing challenges in bridging the gap between Sales and Operations, thus integrated planning becomes the foundational step. The "Mastering Sales and Operations Planning" blog is highly recommended for supply chain leaders who aim to proactively adapt to digital transformation by leveraging diverse S&OP processes and tools.

Businesses while devising their sales strategies try to view things from the customer's perspective by asking themselves questions like "What do customers want?", "How can we make customers happy?", and "What are the most effective upsell strategies?".

While prioritizing the customer is crucial, a company cannot deliver exceptional customer experiences if it struggles to communicate effectively, lacks collaboration among departments, or has other internal issues that require fixing.

This is where Sales and Operations Planning (S&OP) plays a critical role. S&OP focuses on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction. It is among the most valuable tools available for establishing and maintaining internal business health.

The term S&OP may be referred to differently depending on the industry or organization. For instance, some may call it Sales, Inventory, Operations Planning (SIOP), or Integrated Business Planning (IBP). Despite the variation in name, these terms generally describe the same process. What's important to highlight are the concepts of planning and alignment, which are fundamental to the success of this process.

Let’s Further Dive Into the Fundamentals, Process, Purpose, and tools of S&OP

S&OP stands for Sales and Operations Planning. It is a management process employed by businesses that involve meetings between leadership and executive teams to ensure that each business function is properly aligned to balance supply and demand. This process entails collaboration across various organizational departments to create comprehensive predictions for expected sales.

By implementing S&OP, companies can ensure that a company's operational plan is in line with its sales plan which improves their ability to forecast customer demand, manage inventory, and optimize production schedules. This can help to reduce costs, improve customer satisfaction, and increase profitability over the long term.

What is the purpose of Sales & Operations Planning?

S&OP's goal is to establish alignment across the entire organisation. Companies can harness S&OP benefits through the following steps: -

1. Eliminate Departmental Silos - The collaboration opportunity that S&OP fosters are where its true worth lies. Eliminating departmental silos enables a company's various divisions to coordinate using common data sources, which frequently results in higher accuracy, more efficiency, and cheaper costs.

Organisational collaboration is very crucial however unless every department is aligned via a single S&OP process, it’s nearly impossible to achieve.

2. Improved Inventory Management - Effective inventory management is critical to the success of any business. Insufficient production capacity can lead to customer dissatisfaction and potential harm to a company's reputation. According to a study, after three stockouts, 70% of potential buyers will completely switch to a different brand. By implementing an S&OP process plan that considers customer buying patterns and the company's ability to meet demand, inventory management can be significantly improved.

3. Enhanced demand forecasting and budgeting - S&OP enables organizations to forecast customer demand more accurately. By analysing historical data and market trends, S&OP can help to predict demand levels for specific products or services. This allows companies to adjust production levels and inventory levels accordingly.

4. Reduced lead times - S&OP can help businesses to reduce lead times by improving forecasting, streamlining production, optimizing inventory levels, managing suppliers more effectively, and promoting collaboration between different departments. By implementing S&OP, businesses can achieve significant reductions in lead times, leading to improved customer satisfaction and increased profitability.

5. Higher Product Quality - A sales operations plan should result in improved product quality compared to what your company previously produced. This is because an efficient process can minimize mistakes, enabling your organization to produce higher-quality goods quickly. Additionally, better products can lead to cost savings. Every defective product produced by your company must be remade, leading to the wastage of materials and employee resources.

6. Better Customer Service - Delivering excellent customer service is a fundamental aspect of any thriving business. With S&OP solutions when you produce superior products and ensure timely delivery to your customers; This can lead to 50% improvement in your customer service.

Satisfied customers are typically long-term buyers. As it costs significantly less to retain a customer than to acquire a new one, it's crucial to prioritize customer satisfaction. Doing so can enhance your brand's reputation among its target market.

7. Higher Profitability - The six benefits of sales and operations planning process mentioned above lead to increased profitability for businesses by increasing the companies’ responsiveness to eliminate silos, accurately predict inventory needs, improve demand forecasting and product quality, and enhance customer service. With the help of S&OP, organizations can smartly optimize operations to see a 15% increase in sales and drive profitability.

According to Forbes Survey, 100% companies are doing some form of sales & operations planning but only 15% are easily balancing plans horizontally between sales/marketing teams & operations teams whereas, 43% of companies either emphasising more on “S – Sales & Marketing” or “O - Operations” and the process is out of balance.

Do you know the reason behind this imbalance in planning?

Because none address “Effective Sales & Operations Planning”

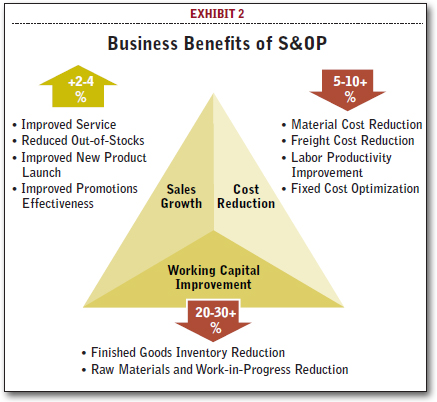

With “Effective” Sales and Operations Planning, companies can drive dramatic improvements in key business performance metrics.

By effective sales and operations planning implementation, businesses can:

According to research, Effective S&OP leads to 2-4% growth in sales through improved services, new product launches, and promotion effectiveness. It also reduces costs by 5-10% through fixed cost optimization, resulting in 20-30% lower working capital in the supply chain.

If you’re interested in Sales Planning, you can read up on the Evolution of Sales Planning through Anaplan

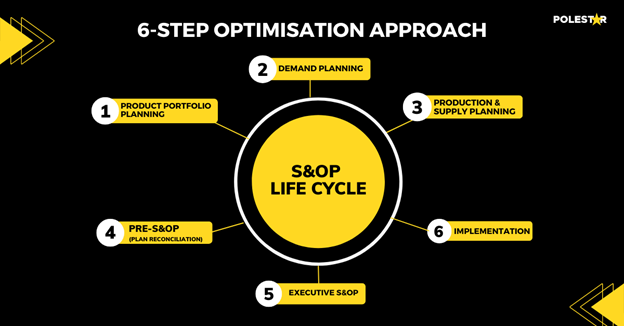

The level of involvement in the development and implementation of S&OP (Sales and Operations Planning) can vary depending on the size of the business. Data collection & product portfolio planning (forecasting) is the first step in the process, which ends with the full implementation of the plan. But you're probably asking how can sales and operations planning be integrated with your strategies.

Here are the six steps of the S&OP process that can solve your above query & lead to integrated business planning.

1. Product Portfolio Planning – During this first phase of the S&OP process, product planners who are involved in R&D, product development, and new product introduction evaluate the market performance of current products, review product pipelines, and make decisions regarding product planning based on their findings. To decide project priority and resource allocation, these decisions may involve defining dates for new production or sunsetting. A new product's impact on old products, also known as cannibalization, is another step covered in this phase.

2. Demand Planning - This phase aims to create a comprehensive demand plan, combining both independent and dependent demand factors such as marketing, trends, and interplant demand. The plan is based on sales, marketing, and product plans and is measured in units or revenue. The process involves statistical forecasting, input from customers and marketing, and historical performance analysis to refine and establish a consensus plan. The plan is then reviewed by finance to identify any revenue or demand gaps.

3. Production & Supply Planning - A supply plan that aligns with the consensus demand plan is the objective of this phase. These two strategies should ideally complement one another. The supply strategy should balance customer service, reduce inventory, and lower operating costs. Along with alternate supply plans that take capacity and demand changes into account, a baseline production plan and a rough-cut capacity plan are created. A technology platform that can perform "what-if" scenarios utilising real-time data is vital because they are a fundamental component of this stage. These scenarios range from more tactical "what-if" queries to longer-term scenarios, but all serve the same purpose: to lower risk and comprehend the benefits and drawbacks of a wide variety of alterations.

4. Pre-S&OP - Pre-S&OP is a series of meetings with leaders at different levels that explain how planning for products, demand, supply, and finances are interconnected. These discussions ought to be centred around a cloud-based platform where all the plans are kept in a single place. The goal of pre-S&OP is to locate significant gaps and disconnects and develop solutions for them. Shared s&op dashboards are used to review the plans, and the actual vs. variance is examined while keeping targets and budgets in mind. To understand the financial and operational consequences of actions, various metrics such as sales, profit, and inventory are examined at both the corporate and product-line levels. Plans for the supply, demand, and product are constantly being adjusted.

5. Executive S&OP – In the concluding phase of enterprise Sales and Operations Planning, all the information and strategies are consolidated into a unified platform based on the cloud, which will be utilized during executive S&OP meetings. Decision points are highlighted so that leadership is aware of when it will be necessary to make the right decisions. "What-if" scenarios and the related risks are assessed. The causes for escalation are looked at, decision dates are established, and any significant decisions that were not resolved in the prior five phases are handled in this phase.

6. Finalise and implement S&OP - Every leader of a department collaborates cross-functionally and with their team to make the necessary revisions to the plan. It is advised to regularly evaluate the implementation.

Refer to the detailed guide here

In today's fast-paced and ever-changing supply chain, making informed decisions is crucial to success. Supply chain leaders need to react quickly to shifting demands and customer needs to optimize margins and maximize profits.

Sales and Operations Planning (S&OP) software is a vital tool for businesses, enabling the harmonization of sales forecasts, production schedules, and sales inventory operations planning. It streamlines resource allocation, minimizes risks, and improves customer satisfaction by fostering collaboration across departments. Through data analytics and forecasting, it optimizes inventory, production, and distribution, enhancing operational efficiency and cutting costs. This integrated S&OP software provides better visibility, agility in responding to market shifts, and ultimately boosts profitability and competitiveness.

| Aspect | How Anaplan helps |

|---|---|

| Essential Functionality | |

| Efficiency Enhancement | |

| Strategic Advantages |

This integrated S&OP software provides better visibility, agility in responding to market shifts, and ultimately boosts profitability and competitiveness.

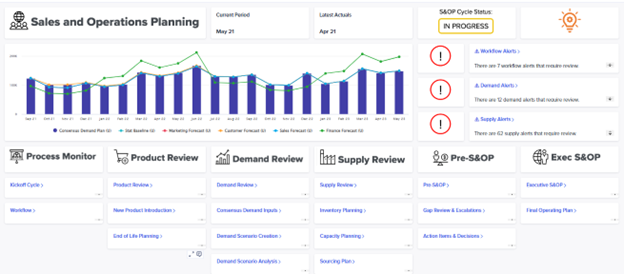

Anaplan, offered on the cloud-native platform, offers a comprehensive approach to supply chain management. It provides real-time visibility across the network, enables demand sensing and driving, and facilitates dynamic and collaborative sales and operations planning (S&OP). With this solution, forecasts become more accurate, silos break down, and connections are strengthened, leading to the achievement of business goals.

The above dashboard showcases various stages in the S&OP (Sales and Operations Planning) process, ranging from monitoring to product review, demand review, supply review, Pre-S&OP, and Exec S&OP. It provides a clear view of the S&OP cycle status for your organization, enabling you to stay informed about the current progress and identify areas for improvement.

At Polestar Analytics, we have been helping customers to unearth a multitude of hidden possibilities and remove dragging impediments through Anaplan software for streamlining Sales & Operations Planning.

Anaplan offers a cloud-based platform that unifies sales and operations planning (S&OP) across all relevant business units. By synchronizing plans and data from various functions such as sales performance management, financial planning and analysis, product, and marketing planning, and supply chain, executives can make well-informed decisions that lead to greater profitability.

We’ve served the world’s leading kitchen and laundry appliance company, by reinventing sales & operations processes by implementing Anaplan which altogether established transparent, connected & agile processes through automation.

Mastering Sales and Operations Planning (S&OP) is a crucial aspect of driving organizational success and achieving operational excellence. This comprehensive guide has provided valuable insights and practical strategies to help businesses navigate the complexities of S&OP implementation enabling cross-functional collaboration, fosters a culture of continuous improvement, and lays the foundation for sustainable growth.

By understanding the core principles of S&OP, aligning sales and operations functions, and leveraging advanced technologies, businesses can optimize their supply chain, improve forecasting accuracy, enhance customer satisfaction, and drive profitability.

Effective S&OP empowers organizations to make informed decisions, balance demand and supply, mitigate risks, and capitalize on market opportunities. It enables cross-functional collaboration, fosters a culture of continuous improvement, and lays the foundation for sustainable growth.

Through the mastery of S&OP principles and the application of best practices, businesses can gain a competitive edge, adapt to changing market dynamics, and enhance overall performance. By implementing the six steps optimization approach outlined in this guide, businesses can embark on a journey towards achieving excellence in enterprise Sales and Operations Planning.

If you’re interested in our services offering Sales & Operations Planning through Anaplan, you can visit our website

About Author

Marketing Consultant

Data Alchemy can give decision making the golden touch.