Sign up to receive latest insights & updates in technology, AI & data analytics, data science, & innovations from Polestar Analytics.

Editor's Note- This article delves deep into the intricacies of demand planning and explores how it can unlock excellence for retail and CPG organizations in a dynamic market. It also talks about the actionable insights and practical tips that can help your organization develop robust demand planning processes and enhance its competitive edge.

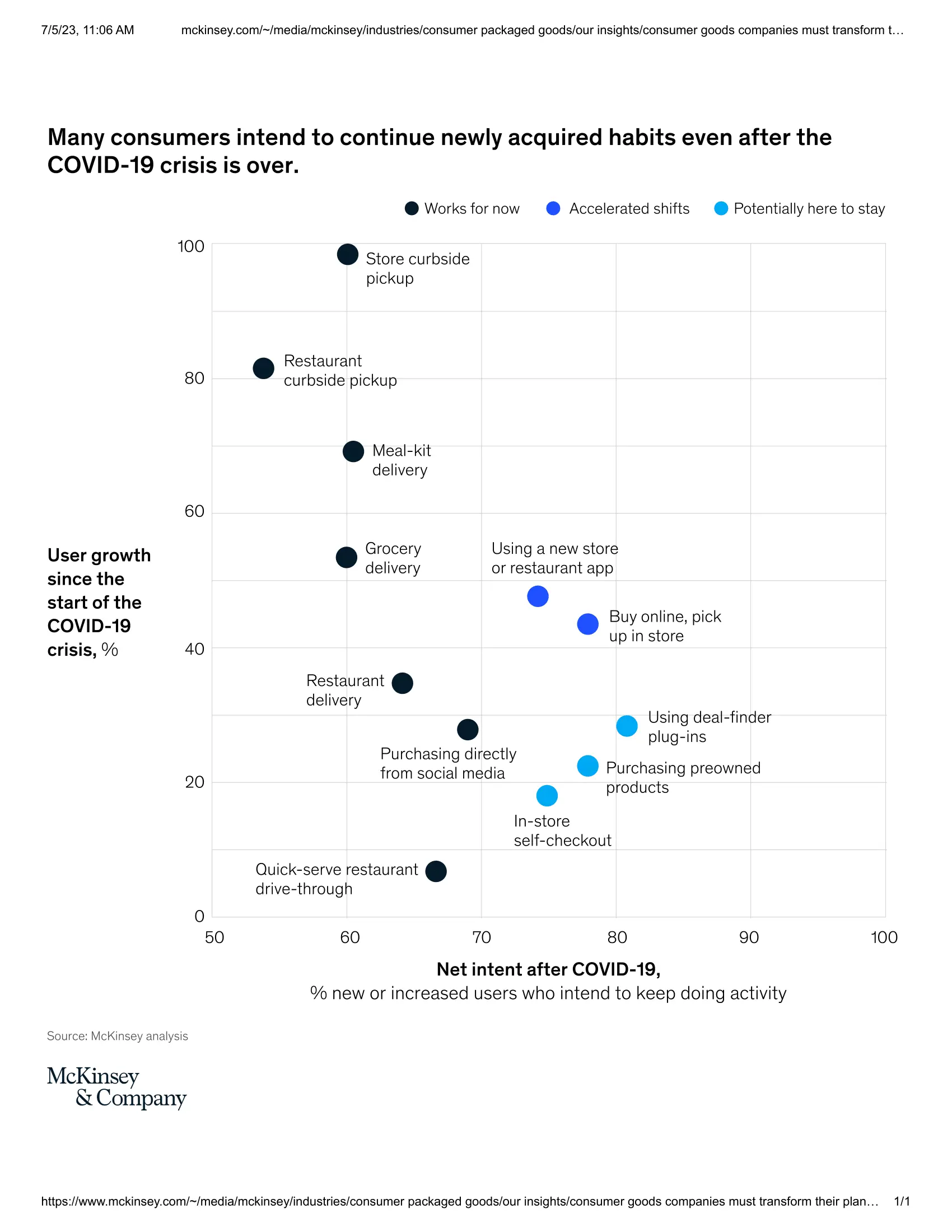

Over the past few years, the retail landscape has been a battleground of uncertainty, revealing the daunting task of predicting consumer desires. Retailers find themselves grappling with the enigma of deciphering and meeting ever-shifting customer demands. As categories undergo massive upheavals and even the line between goods and services blurs, a myriad of factors now influences consumer behavior like never before.

In this dynamic environment, we witness the constant change along well-established demand curves, but also witness the seismic shifts that completely reshape those very curves. The corresponding elasticity of these changes adds another layer of complexity. Compounding the issue are the relentless supply chain challenges that have plagued the retail industry for years, casting an ominous shadow over accurate prediction.

Consider, for instance, the rise of a mercurial and sustainability-driven shopping mindset sweeping across customers worldwide. This shift in consumer expectations has forced retailers to reassess their entire product/service offerings. Adapting to this new reality is no longer optional but imperative.

Yet, these challenges are merely the tip of the iceberg. Retailers find themselves self-inflicting wounds by creating staffing shortages, leaving customers exasperated, and, in some cases, severing their once-loyal ties with beloved products and brands. The stakes have never been higher, and the consequences of misjudgment have never been more severe.

In this type of remarkably complex environment, the question arises: what is the antidote to this chaos? The answer lies in the power of robust planning, deployed intelligently. A strategic approach can unlock a treasure trove of solutions to tackle these multifaceted issues head-on. It offers a beacon of hope in the face of uncertainty, providing retailers with the tools to navigate the storm and emerge stronger than ever before.

Embracing this transformative planning approach is not merely a luxury—it is a necessity. It is the key to decoding the enigmatic desires of consumers, maintaining a competitive edge, and thriving in an ever-evolving retail landscape. In the quest for success, those who dare to embrace the power of robust planning shall emerge as the true champions of this complex, unpredictable retail world.

“Demand forecasting, or demand planning, is a business process where you predict the customer demand for products based on existing trends and data.”

It refers to the use of analytical techniques, tools and methodologies to analyze and derive insights from historical data, market trends, customer behavior, and other relevant factors in order to forecast and plan future demand accurately. It involves leveraging data and statistical models to make informed decisions regarding inventory management, production planning, sales forecasting, and supply chain optimization. To ensure success, precision in demand planning is non-negotiable, safeguarding against potential pitfalls and unlocking the path to prosperity.

In the retail and CPG industry, sales, profitability, and consumer satisfaction stand as crucial objectives. Effective demand planning in CPG serves as a powerful catalyst for achieving these goals. Yet, attaining them is not without challenges, as it necessitates substantial coordination and collaboration among various business units. Additionally, the availability, timeliness, and quality of point-of-sale (POS), inventory, and third-party data play a pivotal role in this process.

Failing to establish and execute reliable demand planning practices rooted in precise data and forecasts can lead to numerous adverse and expensive consequences for both your organization and your retail partners such as -

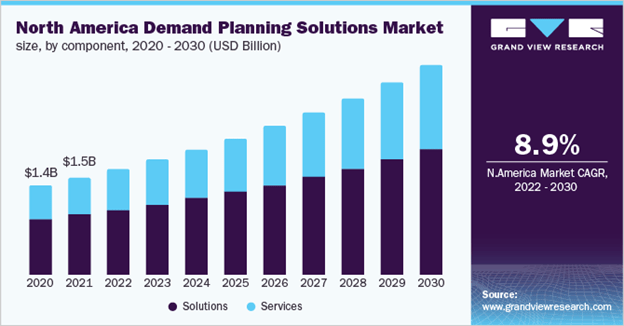

The process of planning in retail industry process can be intricate, particularly in the face of growing e-commerce and omnichannel retailing. However, given that numerous sales, marketing, and operational decisions hinge on consumer demand for CPG products, it becomes imperative for companies to deploy accurate and efficient demand plans, revisiting and adjusting them regularly. By appropriately aligning inventory levels to cater to consumer preferences across various shopping channels and by harmonizing sales and operations processes, retailers and CPGs can unlock a multitude of benefits and advantages such as -

Gain insights into consumer trends, historical data, and market forecasts to accurately forecast demand, minimize stockouts, and reduce excess inventory.

Explore Our Data Analytics ServicesNow, let's delve into some of the key processes encompassed in demand planning, enabling organizations to adeptly manage their demand forecasts and optimize inventory levels.

Trade promotion management focuses on planning and managing promotional activities to influence consumer demand for a product. It involves designing and executing promotional campaigns, such as discounts, coupons, or special offers, to increase sales during specific periods. Trade promotion management aims to align promotional activities with demand forecasts and ensure that the supply chain can meet the increased demand generated by promotions. It involves tracking and analyzing the impact of promotions on demand patterns, assessing their effectiveness, and adjusting future promotional strategies accordingly.

Product portfolio management involves managing a company's portfolio of products or services to meet customer demand effectively. It includes assessing and categorizing products based on various factors such as profitability, growth potential, market trends, and customer preferences. By analyzing the performance of each product in the portfolio, organizations can make informed decisions about product introduction, discontinuation, or modifications. Product portfolio management helps optimize the allocation of resources, streamline production and distribution, and align the product mix with customer demand to maximize overall profitability.

Statistical forecasting is a data-driven approach to predicting future demand based on historical data and statistical models. It involves analyzing past sales data, market trends, seasonality, and other relevant factors to generate accurate forecasts. Statistical forecasting techniques include time series analysis, regression analysis, moving averages, exponential smoothing, and more. By leveraging statistical forecasting, organizations can estimate future demand at different levels, such as product SKUs, product categories, or geographical regions. These forecasts serve as a basis for production planning, inventory management, procurement, and supply chain optimization.

So, these elements of demand planning processes can enable organizations to make informed decisions, optimize their operations, and meet customer demand effectively.

Demand planning involves multiple steps and can become increasingly complicated as businesses and data requirements expand. Successful companies adopt various best practices to enhance the efficiency, collaboration, and effectiveness of their demand plans. Now, let's explore a modern perspective on demand planning.

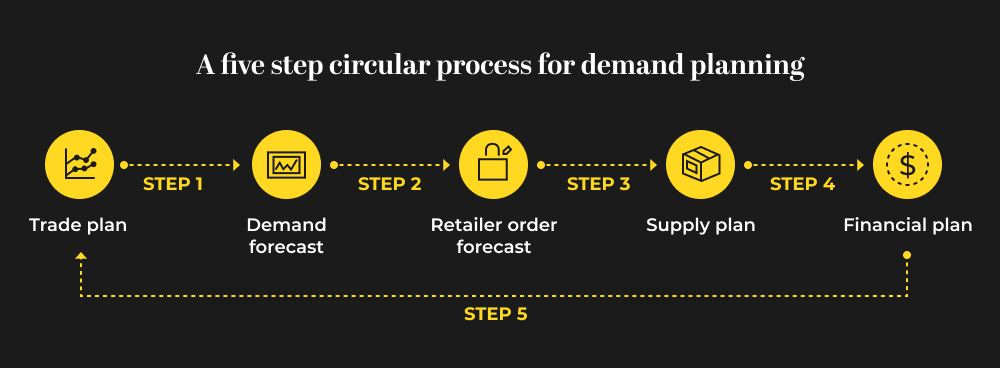

Step 1: Trade plan The team combines trade planning information, including upcoming promotions and marketing investments, with the aforementioned data to generate a comprehensive demand forecast. The forecast encompasses a comprehensive range of SKU, retailer, and week combinations, spanning the entire planning horizon.

Step 2: Demand forecast Utilizing the demand forecast derived from Step 1, the team incorporates historical shipment data of CPG-to-retailer transactions to generate a forecast for each retailer's future orders. The forecasting process ensures a meticulous level of detail, covering individual SKUs and weeks throughout the entire planning horizon.

Step 3: Retailer order forecast The team transforms the shipment forecast into a supply plan, which takes into account various factors such as available materials (including raw material inventories) and manufacturing capacity constraints. The aim is to optimize specific performance measures while formulating the supply plan.

Steps 4 & 5: Supply and financial plans The team consolidates the retail SKU and weekly forecasts, resulting in a brand-level financial forecast for each month throughout the planning horizon. Following that, they conduct a thorough comparison between the financial forecast and the company's business objectives and trade plan, aiming to ensure seamless alignment and evaluate overall performance.

Our comprehensive CPG analytics solutions can accelerate your operations by providing real-time insights into consumer demand.

Talk to Our Industry ExpertRetail Demand Planning is a critical process in the retail and consumer packaged goods (CPG) industry. To ensure effective demand planning in retail, the following best practices can be adopted:

Therefore, accurate demand planning and forecasting provide consumer packaged goods (CPGs) and their retail partners with a distinctive advantage, empowering them to proactively anticipate and fulfill future consumer demand while minimizing surplus inventory and reducing costs. By seamlessly integrating CPG demand planning into their sales and operational strategies, businesses can achieve enhanced efficiency, and profitability, and elevate customer and consumer satisfaction to new heights.

If you're eager to make retail analytics services a central component of your strategic decision-making process and stay ahead of the curve, reach out to our team of retail and consumer packaged goods (CPG) experts today. Let us guide you toward success.

About Author

Content Architect

The goal is to turn data into information, and information into insights.