Sign up to receive latest insights & updates in technology, AI & data analytics, data science, & innovations from Polestar Analytics.

93% of companies believe AI is crucial for manufacturing growth. Yet 74% struggle to get any value from AI implementations. You're either in the 26% that's winning, or you're about to get crushed.

The evidence for which is everywhere. China's "AI Plus" initiative launched in March 2024 specifically targets manufacturing digitalization to capture larger market share through operational efficiency. European manufacturers face energy costs 3x higher than Asian competitors, making autonomous optimization critical for survival.

Here's what's driving the urgency: By 2028, 33% of enterprise software applications will incorporate agentic AI, up from less than 1% in 2024. The $5.94 billion market expanding to $230.95 billion by 2034 isn't speculation—it's capital deployment toward competitive advantage.

Look, we get it—another AI trend alert makes your eyes glaze over. But here's the thing: this isn't about jumping on the latest tech bandwagon. 32% of top executives globally place AI agents as the top technology trend for 2025, but smart manufacturers stopped caring about trends when their competitors started cutting production costs while they were still coordinating maintenance schedules.

Manufacturing runs on speed and accuracy. AI has always separated leaders from laggards. But agentic AI isn't about technological superiority—it's about survival.

The stats tell the story.

The numbers show the urgency. But what do manufacturers actually get from this transformation?

We understand that outcomes>buzzwords. So we bring to you these five AI agents that are delivering ROI across production floors, eliminating downtime, and cutting operational costs.

As an AI agent, Predictive maintenance represents the most mature and proven AI agent application in manufacturing. Leading implementations achieve 20-50% reduction in unplanned downtime and up to 30% reduction in maintenance costs.

But here's what separates agentic systems from traditional monitoring: While your vibration sensors and thermal cameras predict failures weeks in advance, AI agents eliminate the coordination bottleneck between prediction and action. These agents constantly analyze real-time sensor data—vibration signatures, thermal fluctuations, current profiles, and acoustic patterns—alongside historical maintenance records to predict potential equipment failures before they happen.

The difference: instead of generating alerts for human teams to coordinate, agents automatically execute work orders, source parts from pre-approved suppliers, and schedule maintenance windows within production constraints. Your planned maintenance actually stays planned.

The global AI agents predictive maintenance market projected to reach $1.811 trillion by 2030.

Reflects a simple reality: autonomous execution delivers ROI that manual coordination can't match.

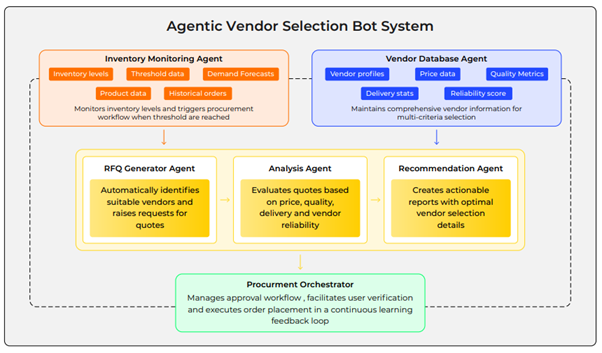

Manufacturing vendor management agents eliminate supplier coordination bottlenecks that create supply chain vulnerabilities. Only 13% of business leaders have formal supplier management processes, while manufacturers manage hundreds of suppliers across complex quality, cost, and reliability matrices.

The system doesn't just identify the cheapest vendor—it constructs optimal solutions balancing immediate needs against long-term strategic objectives.

Get our AI Agents Implementation Guide to deploy autonomous supplier intelligence across your operations.

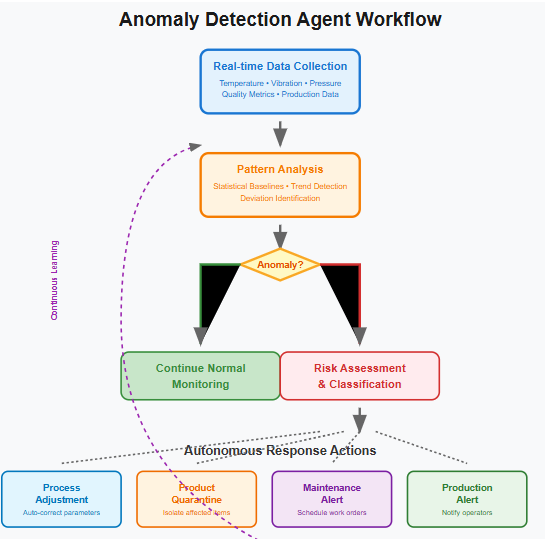

Manufacturing anomaly detection agents monitor production processes in real-time to identify deviations before they cause quality escapes or equipment failures. Unlike traditional SPC methods that react to problems after production, these agents integrate with your existing process historians (OSIsoft PI, Wonderware) and MES systems to provide continuous monitoring across:

The agent processes multi-variate data streams through advanced algorithms to detect three critical anomaly types i.e., Point Anomalies (Single data points outside normal operating ranges (sudden pressure spike, temperature excursion) , Contextual Anomalies (Values normal individually but abnormal in specific contexts (acceptable vibration during startup, problematic during steady-state operation)) and Collective Anomalies(Patterns indicating emerging issues (gradual drift in multiple parameters suggesting tool wear or calibration drift).

These systems use unsupervised machine learning—including Isolation Forest and Local Outlier Factor algorithms—to identify deviations from normal behaviour patterns.

The result: immediate corrective actions that significantly reduce waste and quality issues.

AI-driven procurement platforms deliver measurable results: 20-35% average cost savings, 30% increase in process efficiency, and 25% faster procurement cycles.

But here’s what’s falling short. The Manufacturing Procurement Problem: Your production line component shows degradation patterns. Procurement initiates standard sourcing procedures requiring competitive quotes, vendor evaluation, and approval workflows. The component fails during the evaluation process. Emergency procurement becomes single-source ordering at premium pricing plus expedited delivery costs.

Here's what the Procurement agent changes.

| Before Agentic AI | After Agentic AI |

|---|---|

| Component degradation detected | Component degradation detected |

| Procurement initiates sourcing procedures | Procurement agents act autonomously |

| Three competitive quotes required | Pre-qualified suppliers queried instantly |

| Vendor evaluation and approval workflows | Contracts executed within approved frameworks |

| Component fails during evaluation process | Parts sourced before failure occurs |

| Emergency single-source procurement | Planned procurement at standard pricing |

| Premium pricing + expedited delivery costs | Negotiated rates + optimized delivery timing |

Impact: Emergency procurement becomes planned procurement. Reactive repair becomes preventive maintenance.

Your planning team can't optimize across thousands of part numbers, multiple production schedules, and dynamic supplier constraints simultaneously. Manual inventory management creates either excess working capital or production delays from material shortages.

One of the areas where agentic AI truly shines is inventory management

Check out this video of Ankit Rana, CIO of Polestar Analytics, explaining how autonomous inventory agents eliminate manufacturing stockouts and reduce carrying costs.

20-50% reduction in holding costs with 10-20% improvement in service levels through dynamic optimization that anticipates manufacturing demand before planners recognize emerging requirements.

Discover the Order Management Agent that transforms complex manufacturing orders into 30-minute autonomous execution.

Implementation drives results. Here's what our AI agents deliver when properly deployed.

1. Speed that matters: Autonomous decision-making eliminates weeks of human coordination. Problems get solved while alerts are still generating.

2. Accuracy that scales: 90% defect detection accuracy with continuous learning that improves over time.

3. Costs that drop: 30% reductions in supply chain and quality control operations through autonomous optimization.

4. Operations that self-optimize: Production lines adjust automatically. Maintenance schedules itself. Quality control prevents rather than detects.

These five agents are just the beginning. Dozens of manufacturing operations need autonomous systems—from production scheduling to energy management.

The fact is Manufacturing companies must take decisive action to integrate autonomous, intelligent systems into their operations. To maintain competitive advantage in an increasingly automated industry, prioritize your operational focus: "Asset Optimization," "Production Excellence," "Supply Chain Resilience," or "Quality Innovation." Check out our manufacturing use case quadrant for strategic guidance.

Your entry point matters. While competitors evaluate strategies, successful manufacturers start with immediate pain points: equipment failures, quality escapes, or supply disruptions.

The competitive window is closing rapidly. The future belongs to manufacturers who deploy intelligent, self-optimizing systems before their competitors. It's no longer about analyzing production data—it's about autonomous systems that act on that data to optimize operations, prevent failures, and maximize output with precision and speed.

Ready to explore AI agents for your manufacturing operations? The competitive advantage belongs to those who act while others are still planning.

About Author

Content Architect

The goal is to turn data into information, and information into insights.