Supply planning performance management

Master the art of supply planning and achieve operational excellence through cutting-edge management strategies.

With a decade-long experience in Supply Chain planning and a roster of vastly competent model builders and industry experts, Polestar Analytics orchestrates seamless planning across your enterprise and supply network with end-to-end visibility.

Our Supply chain planning architecture:

Coordinate across your supply chain operations and the wider supply chain by fusing together people, procedures, technological infrastructure, and data.

Make course corrections possible within hours by creating center-to-edge alignment. Switch whole networks in a few of days while staying ahead of demand fluctuations and meeting delivery goals.

Quantify cost-cutting opportunities for the supply network with smart visualizations of shipments. Create optimal loads and unlock savings opportunities.

Unify siloed data to generate real-time, end-to-end insights and extend decision intelligence and business automation with AI-/ML-based supply chain analytics across the enterprise.

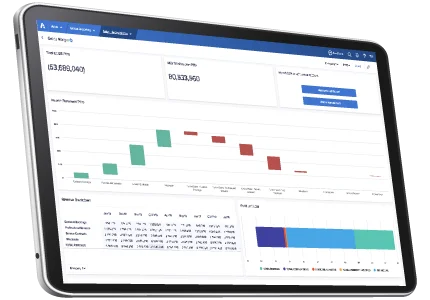

Simulate & optimize operations, monitor performance in real-time, & collaborate with stakeholders. By leveraging these virtual representations, planners can enhance overall efficiency & responsiveness.

Prioritize modes of transportation according to impact, and use statistics to track the emission sources. Develop a robust ESG plan for your supply chain involving partners and suppliers.

Orchestrate our seamless solutions across your enterprise and supply network with end-to-end visibility for accurate and integrated decision making.