Sign up to receive latest insights & updates in technology, AI & data analytics, data science, & innovations from Polestar Analytics.

In today’s fast-paced market, optimizing the CPG supply chain is more critical than ever. Our latest blog highlights how autonomous supply chain planning, powered by AI and ML, is revolutionizing efficiency and responsiveness in the CPG sector. Discover how embracing these technologies can enhance accuracy, reduce costs, and drive sustainability. Dive in to explore the future of CPG value chain!

CPG companies find themselves at a pivotal moment, requiring the evolution of their planning systems to adapt to changing circumstances.

The ongoing crisis has severely impacted many Consumer Packaged Goods (CPG) companies, driven by factors such as rising raw material costs, supplier uncertainties, increasing inventory levels, and unpredictable demand patterns. These challenges, compounded by global disruptions like geopolitical shifts, regulatory changes, and natural disasters, continue to threaten both top-line growth and profitability.

Traditional supply chain planning methods, which rely heavily on historical data, are proving inadequate in addressing these complexities. They often fail to account for forward-looking external factors, making it difficult for CPG companies to adapt swiftly to evolving consumer behavior, such as the shift from brick-and-mortar stores to online shopping or scaling production to meet sudden demand surges.

According to McKinsey’s CPG Asia Survey, about 80% of CPG companies still rely on traditional or collaborative Sales and Operations Planning (S&OP) processes, with limited real-time decision-making and automation. This approach requires direct involvement from COOs and operations teams to manage interdependencies between systems, often resulting in delays due to manual interventions. Autonomous supply chain planning offers a solution to these challenges by enabling faster, more efficient decision-making.

Autonomous planning is a constant, closed-loop planning approach built on a fully automated technology platform to optimize real-time processes. For large, complex organizations, autonomous planning can help supply chain solutions function more effectively in volatile environments and require less direct human oversight and decision-making. It combines big data and advanced analytics at every step of the supply chain planning process.

Download this guide to chart your course toward an innovative and efficient supply chain future with Generative AI

Download eBookThe autonomous supply chain planning process leverages advanced technologies such as Artificial intelligence (AI) and Machine learning. It holds up the evaluation of millions of data points and the generation of insights from them.

Businesses will better understand current and historical supply and demand to determine the best course of action to keep pace with the customer requests, regardless of market conditions.

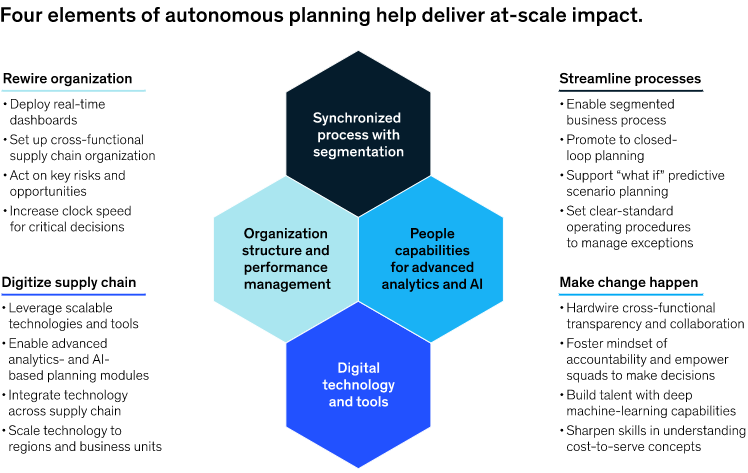

Although it is entirely based on technology, autonomous planning needs more than software and hardware. That's because it necessitates a shift in the way that organizations work based on a set of foundational principles:

Our extensive autonomous supply chain solutions for the CPG industry will make your organization agile, transparent, granular, and efficient.

Talk to Our CPG ExpertsAlthough it is entirely based on technology, autonomous planning needs more than software and hardware. That's because it necessitates a shift in the way that organizations work based on a set of foundational principles:

As it is so comprehensive, autonomous supply chain planning leads to improved performance in a range of processes across the global supply chain.

Just like we've seen successful applications of autonomous systems in aircraft, automotive, and other transport mechanisms, we are seeing it successfully today in consumer goods. Why? Organizations have reached sheer maturity when it comes to connectivity, their capability to acquire precise data close to the source and store it, and the obtainability of machine learning and advanced modeling techniques to learn from this data.

Additionally, flexible compute architectures enable complex models to learn in high-performance cloud computing environments while being deployed at the "edge" resulting in quick system influence with low latency.

There are multiple autonomous supply chain use cases that CPGs can implement to improve efficiency, reduce costs, and increase flexibility. Here you go:

| Demand Forecasting | Using historical sales data and machine learning algorithms to predict future demand for products, allowing for better inventory management and production planning |

| Purchase Order management | Automating the process of creating, sending, and tracking purchase orders, which can help to reduce errors and improve supplier relationships. |

| Predictive Inventory Management | Utilizing data from sales, customer behavior, and logistics to predict inventory needs and automate replenishment. |

| Transportation Planning | Utilizing optimization algorithms to plan the most efficient routes and schedules for transporting products, which can help to reduce logistics costs and improve delivery times. |

| Production Scheduling | With advanced planning and scheduling systems to optimize the production process and ensure timely delivery of products, which can help to improve efficiency and reduce waste. |

| Quality Control | Applying machine learning and sensor-based technologies to automatically monitor and control the quality of products during production, which can help to improve product quality and reduce defects. |

| Predictive Maintenance | Embedding sensor data and machine learning to predict when equipment will fail, schedule maintenance, and reduce downtime. |

| Autonomous Robots in the warehouse | Implementing autonomous robots to improve warehouse operations, they can navigate through the warehouse, pick, pack, and dispatch orders. |

This guide outlines practical strategies and real-world examples for implementing effective supply chain KPIs.

DownloadTherefore, in the current complex and volatile environment, the consumer packaged goods supply chains can no longer rely on the traditional planning processes. Instead, they should look for a clear opportunity to improve financial and operational performance by implementing autonomous planning across the end-to-end supply chain analytics.

We at Polestar Analytics embrace new technologies, where we help enterprises implement autonomous solutions to ensure that they can compete and thrive regardless of what the future holds to improve the CPG value chains. Book a demo today to understand more about our CPG supply chain solutions.

About Author

Content Architect

The goal is to turn data into information, and information into insights.