Sign up to receive latest insights & updates in technology, AI & data analytics, data science, & innovations from Polestar Analytics.

Editor's Note: Whether you are a seasoned industry professional or someone looking to gain a better understanding of FMCG supply chains, here you go. In this blog, we dissect the strategies that are transforming the FMCG industry, shed light on the latest trends, and provide valuable insights that can help businesses navigate the ever-changing landscape of FMCG. Dive in!

Fast-moving consumer goods (FMCG) form one of the largest industries worldwide. FMCG is an integral part of our daily routines, from the cereal we eat in the morning to the toothpaste we use before bed.

Ever-changing consumer preferences and new technologies constantly disrupt the industry. Customers demand innovative products, which means quickly producing a more comprehensive range of goods at humongous volumes. In emerging economies, consumers are increasingly spending extravagantly, leading to a heightened demand for a more extensive supply chain.

According to a report from Allied Market Research, the worldwide FMCG market is projected to achieve a value of $18,939.4 billion by 2031, displaying a remarkable growth rate of 5.1% over the upcoming five years. However, the Fast-Moving Consumer Goods (FMCG) industry navigates through a complex and unpredictable logistical landscape. Whether it's high raw material costs, increased protectionism, evolving sustainability regulations, or additional import and export licenses, businesses must ensure all requirements are met while maintaining competitiveness.

In the current scenario, new avenues are offering more significant business opportunities. Research from Statista also shows that eComm is growing more instantaneous than traditional brick-and-mortar stores year-on-year. Customers are increasingly seeking new product offerings, such as sustainable and healthier options. This trend is anticipated to create fresh opportunities for players in the FMCG industry.

In this blog, we delve into the world of supply chain management in the FMCG industry, exploring its challenges, strategies, trends, and the role of technology in streamlining operations.

FMCG companies produce and distribute goods with a short shelf life that are consumed quickly. This unique characteristic poses challenges to supply chain management that are less prevalent in other industries.

Forecasting issues: Accurate demand forecasting is pivotal to ensure that the right products are available in the right quantities at suitable locations. However, FMCG products are often influenced by volatile market trends, seasonal fluctuations, and unpredictable consumer preferences.

Inventory imbalances: Balancing inventory levels is a delicate task in the FMCG industry. Maintaining an optimal stock level is crucial to prevent stockouts and excess inventory costs, which can erode profitability.

Distribution Complexity: The FMCG sector often requires multi-tier distribution networks to reach consumers efficiently. Managing these networks, ensuring timely deliveries, and minimizing disruptions can be challenging.

Short Product Lifecycles: FMCG products have short lifecycles due to changing consumer preferences and rapid innovation. This makes it crucial to quickly introduce new products and phase out old ones, all while minimizing disruptions to the supply chain.

What is the FMCG supply chain? It is the network of processes involved in manufacturing, distributing, and selling high-volume, affordable products that consumers buy frequently. Effective FMCG supply chain management is crucial for Fast-Moving Consumer Goods companies because products have a short shelf life, high demand, and low-profit margins. Here are some strategies for managing FMCG supply chains effectively

Collaborative Planning, Forecasting, and Replenishment (CPFR):

CPFR involves sharing information between manufacturers, suppliers, and retailers to improve demand forecasting accuracy. This collaborative approach enables stakeholders to make informed decisions and align their operations with actual market demand.

Just-in-Time (JIT) Inventory: JIT inventory management aims to reduce excess inventory by ordering and producing goods just in time to meet customer demand. This strategy helps minimize carrying costs and the risk of obsolescence.

Supply Chain Agility: An agile supply chain is characterized by flexibility and responsiveness. This approach allows FMCG companies to adapt to demand, supply, or market conditions quickly. Technologies like data analytics and real-time monitoring play a crucial role in enabling agility.

Vendor-Managed Inventory (VMI): VMI shifts inventory management responsibility from retailers to suppliers. Suppliers monitor inventory levels at the retailer's location and replenish stock as needed. This approach reduces stockouts and ensures smoother operations.

Cross-Docking: Cross-docking involves transferring goods directly from inbound to outbound trucks without storing them in a warehouse. This strategy accelerates the distribution process, reducing warehousing costs and enhancing efficiency.

Explore our in-depth blog on "Analytics Use Cases in the FMCG Industry" and unlock the potential of your operations today!

1. Rise of supply chain technology

2. Supply chain agility

3. Sustainability focus is increasing

4. Procurement practices

The FMCG sector heavily relies on cutting-edge technologies for effective supply chain analytics. Within this sector, the backbone of such analytics lies in machine learning and artificial intelligence. These pivotal technologies continuously analyze vast datasets, crafting algorithms that yield responses akin to human decision-making, thus facilitating adept supply chain management.

Simultaneously, the Internet of Things (IoT) operates in the background, diligently gathering and furnishing the raw data for AI-driven processes to function optimally.

In this sector, the convergence of digital twin technology and control tower solutions takes center stage in orchestrating end-to-end supply chain management. Control towers meticulously oversee all facets of supply chain operations, swiftly identifying areas of discrepancy and offering prescriptive measures for rectification. The digital twin concept, which represents a virtual emulation of the actual processes, vividly demonstrates the potential benefits recommended actions can bestow upon the supply chain as a whole.

Gain valuable insights into the world of Supply Chain Control Towers and unlock the potential to optimize your operations, reduce costs, and enhance efficiency.

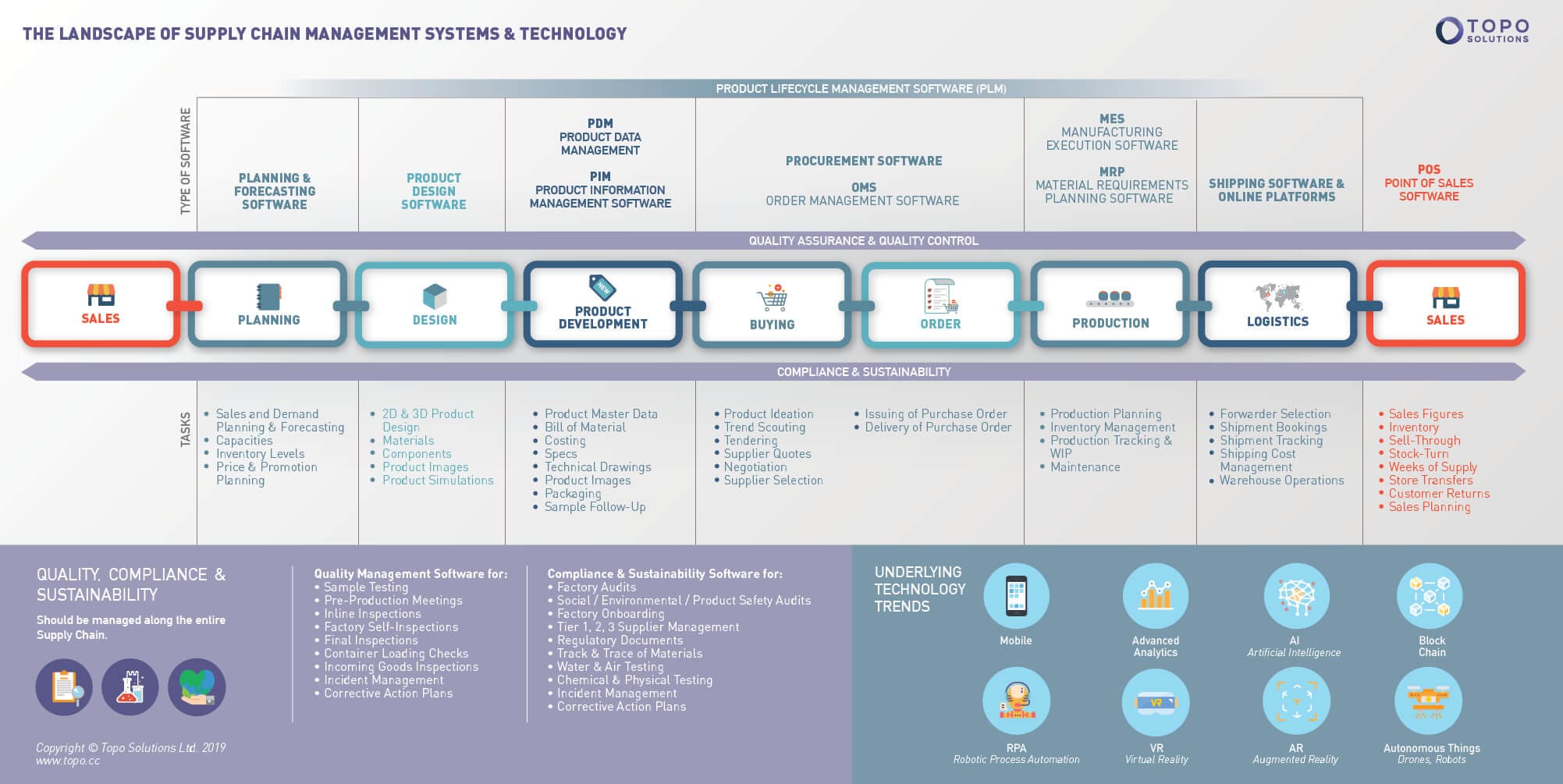

So, explore the ever-evolving realm of supply chain management technology, investigating how both traditional and cutting-edge software and tech solutions can optimize your supply chain operations comprehensively and efficiently.

Within the FMCG context, the synergy between analytics and these advanced technologies seamlessly delivers prompt, pragmatic, and precise solutions, thereby ensuring supply chains' seamless and efficient functioning. This synergy underscores the inseparable partnership between technology and analytics, culminating in providing a robust and economical supply chain management solution.

In the dynamic and rapidly changing Fast-Moving Consumer Goods industry, effective supply chain management is a necessity and a strategic imperative. The ability to adapt, respond, and innovate in the face of evolving consumer preferences, market trends, and external disruptions can determine the success of FMCG companies.

By embracing technological advancements, fostering collaboration, and implementing robust strategies, the FMCG sector can create resilient supply chains that deliver value to consumers, stakeholders, and the environment.

With Polestar Analytics as your partner, take benefit of our in-depth understanding of the FMCG industry to build a more efficient supply chain. We focus on offering agile solutions characterized by digital innovation and safety, led by a global team of highly talented supply chain professionals. Book a consultation today!

About Author

Content Architect

The goal is to turn data into information, and information into insights.