Sign up to receive latest insights & updates in technology, AI & data analytics, data science, & innovations from Polestar Analytics.

Editor Note's: Through this blog, we delve into the transformative power of Advanced Analytics in the FP&A function within the manufacturing industry. As the patterns in demand and supply continue to be unpredictable due to global tensions and adverse economic scenarios, we explore how leveraging cutting-edge data-driven insights can revolutionize financial planning, forecasting, and analysis.

The manufacturing industry is often dubbed as the support system of a country’s economy, and being highly competitive and dynamic makes it crucial for organizations to make informed financial decisions to stay ahead of the competition.

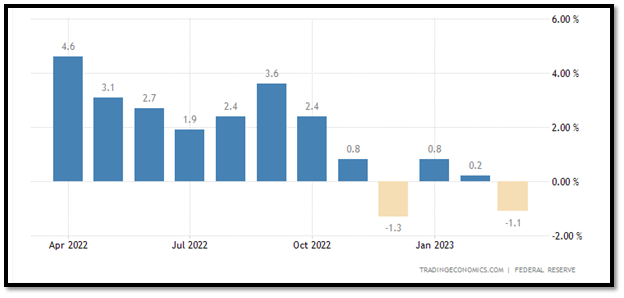

Nonetheless, the industry endured its most severe disruption in over a decade, post the global pandemic. The world is heading into economic uncertainty after the tensions in Russia – Ukraine relations and the subsequent trade embargoes. On the face of it, this seems to suggest slowing growth and declining profits for the manufacturing industry.

With the help of advanced analytics, Financial Planning and Analysis (FP&A) teams in the manufacturing sector can leverage data-driven insights to support better decision-making.

The manufacturing industry has rapidly evolved with new technologies, manufacturing analytics, and advanced insights. These advancements have enabled manufacturers to optimize their FP&A processes by leveraging Analytics and Forecasting capabilities.

This blog will discuss the trends in the manufacturing sector, the use cases of Advanced Analytics in FP&A for manufacturing, challenges faced by the FP&A function of the organizations in manufacturing, and bottlenecks faced by organizations in the adoption of analytics.

The COVID-19 pandemic had significantly impacted how organizations operated, and irregular and uncertain demand and supply had posed a major challenge to manufacturing firms. FP&A teams across the industry faced the brunt of question marks and exclamations over budgeting, resource allocation, and emergency and discretionary spending apprehensions.

The pandemic has caused unprecedented situation in Manufacturing financial planning – leading to declining revenue and profitability. This uncertainty makes it challenging to forecast future financial performance, as traditional forecasting models may not be applicable in the current environment.

The pandemic has made risk management and insurance policies even more crucial. Manufacturing organizations working on heavy CAPEX must have risk mitigation strategies in place. The importance of data analytics in manufacturing industry could advanced data analytics, considering potential risks that may impact the business, such as supply chain disruptions or changes in government regulations. As per a report, 67% of CFOs say they spend significant time on data analysis, FP&A, and scenario planning (NetSuite: CFOs on Profits, Payroll, and Peer Expectations, 2022)

By identifying potential problems early on, manufacturers can take action to prevent them from becoming larger and more expensive to resolve.

The Pandemic has also increased costs for manufacturing companies, with higher raw materials and logistics prices. FP&A teams must develop strategies to manage these costs and optimize their operations. Rising costs have forced many firms to rethink their pricing strategy. A survey by PwC revealed that a third of businesses (33%) have had to adjust their pricing strategy. 30.5% of CFOs expect larger-than-usual net cost increases to continue past the next 12 months (Fuqua School of Business, 2022)

The Covid-19 pandemic has caused significant shifts in consumer behavior, with many people switching to online shopping and limiting their in-person activities. This has resulted in fluctuations in demand for various products, making it difficult for manufacturing companies to forecast their sales. FP&A teams need to develop scenarios that factor in potential changes in demand and consumer behavior.

The pandemic has impacted global supply networks, leading to severe production delays and shortages. This has affected the ability of manufacturing companies to plan and forecast their operations. FP&A teams need to factor in potential disruptions to the supply chain while developing their financial plans and forecasts.

The biggest bottleneck to adopting advanced data analytics for the finance team is the issue of Data Quality and Compatibility. Working across various Systems and Platforms often results in generating data that could be incomplete, inaccurate, or inconsistent making system integration difficult.

Another vital cog in implementing advanced analytics in manufacturing is workforce. Adopting the use of advanced analytics requires a cultural shift towards data-driven decision-making. Some organizations may resist this shift, preferring to rely on intuition and experience. Even if the shift does take place, the expertise to effectively implement thorough manufacturing analytics is beyond the inherent skillset of the FP&A team.

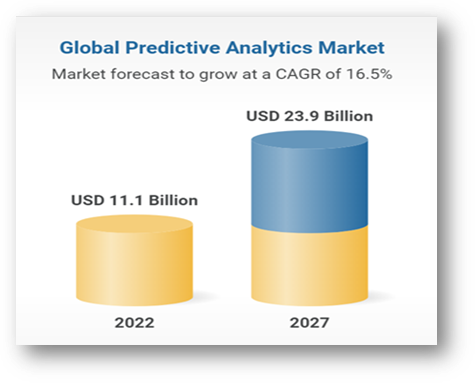

The importance of advanced analytics in manufacturing is undeniable - it is at the heart of the FP&A process because the entire accounting and finance is dependent on it. Collecting, analyzing, and using accurate data is essential for a company’s success, and crucial for the leadership team to make data-driven decisions. A 2021 Report by Gartner indicated 57% of finance organizations plan to invest in advanced data analytics technologies and tools in the next three years (Gartner, 2021)

As per a survey, 36% of CFOs think accurate forecasting will be their biggest challenge in the next 12 months (Gartner, 2022).

Advanced technologies like digital twins, IoT, artificial intelligence, machine learning, etc., significantly impact day-to-day operations, reduce production costs, and better serve client needs. Artificial intelligence (AI) is equipping businesses with new capabilities by automating tasks and enabling more efficient processes.

Implementing an effective mechanism for advanced analysis in finance can reap huge rewards from the Financial Planning & Analysis standpoint.

1. Reduction in operational costs:

Advanced analytics can help to analyze data to vastly reduce operational costs. Organizations that have invested in advanced analytics have been shown to reduce maintenance costs by 10-40%, reduce downtime by 30-50%, and increase equipment utilization by 20-50%, as per a report by McKinsey. The FP&A team can identify cost drivers, predict future costs, optimize pricing structure, and monitor tail-end spending with the help of advanced data analytics. While these can often be small, cumulative savings can be substantial.

2. Effective sales forecasting:

A study by the Aberdeen Group suggests that companies that use advanced analytics for sales forecasting achieve a 10.6% increase in year-over-year revenue compared to companies that don't use advanced analytics. This is primarily the outcome of Advanced analytics – forecasting sales by analyzing historical sales data, market trends, and customer behavior.

3. Preparing and managing budgets for various functions:

Apart from this, a robust and dedicated FP&A Consulting can help the finance department identify patterns and trends in data from multiple sources and predict whether budget allocations are likely to deliver the desired ROI. Companies can use historical data to predict the best possible ways to allocate resources and avoid underspending or overspending.

A liquidity assessment is a primary activity a manufacturer needs to properly plan and forecast. Ultra-thin profit margins require raising or borrowing capital for investment before you need it to maintain continuous operations.

4. Optimizing R&D and production costs:

Manufacturing analytics could also go a long way in Optimizing the R&D costs of an organization. General Electric had used Advanced Analytics to detect quality issues early in production, reducing waste and improving product quality – resulting in a 50% reduction in warranty costs.

Advanced analytics can forecast future capacity needs by analysing historical production data, market trends, and customer demand. This can help manufacturers optimize their production process, reduce costs, and improve efficiency.

5. Devising the correct supply chain strategy:

The supply chain and logistics function takes up considerable expenses for a manufacturing firm. The FP&A team must devise an optimal strategy to balance the effective functioning and costs involved. Manufacturing analytics can help manufacturers optimize their supply chain by predicting demand, reducing inventory costs, and improving delivery times. For example, PepsiCo used advanced analytics to optimize its supply chain, resulting in a 10% reduction in transportation costs.

Get access to advanced insights to unlock the full potential of FP&A in manufacturing. Stand out with superior financial planning and better decision making.

Starting with Advanced analytics can be daunting, especially for organizations that are used to traditional forecasting and planning methods:

The first step in implementing advanced analytics is to change how you forecast. This may involve moving away from traditional forecasting methods, such as historical trend analysis, and adopting more sophisticated techniques that incorporate statistical modelling and machine learning.

It is essential to quickly identify the business reasons for implementing advanced analytics. This may include improving accuracy, reducing forecasting time, and identifying new opportunities or risks. By identifying the business reasons, you can ensure that the implementation process is focused and aligned with organizational goals.

Advanced analytics can fundamentally change the meaning of planning and budgeting. It is crucial to communicate the benefits of advanced analytics to stakeholders across the organization to make a case for changing the purpose of planning and budgeting.

It may take a long time to convince management to change your company's forecasts significantly. Nonetheless, implementing a connected planning tool like Anaplan not only helps the FP&A teams of the Manufacturing sector to automate their financial planning process but also provides the power of analytics to unearth business Insights.

In conclusion, advanced analytics can offer significant benefits for manufacturing companies in FP&A, but several challenges and bottlenecks need to be overcome. By addressing these issues, companies can unlock the full potential of advanced data analytics and gain a competitive advantage in the marketplace.

To equip your FP&A Function with your Advanced Analytics insight, get in touch with our industry experts.

Reach Polestar Analytics now!

About Author

Sports and Tech Enthusiast

In a world of opinions and cold numbers, data tells a compelling story.