Editor’s Note: Procurement can be so much more than a cost center. This blog is your blueprint for transforming sourcing into a strategic powerhouse that drives innovation, mitigates risk, and delivers tangible value to your bottom line. We'll cover everything from data-driven decision-making to cutting-edge technology adoption. Get ready to elevate your procurement function.

What comes to your mind when you hear about the Sourcing/Purchasing/Procurement teams?

Supplier Relationships….Inventory levels….Buffer Stock….Negotiating best price contracts? All of these are traditionally perceived as having manual touch points and human interaction.

However, in the midst of these manual touchpoints and peer interactions a lot of data gets overlooked and organizations fail to paint the full picture – 69% of companies do not have total visibility of their Supply Chain! [Source]

83% of Supply Chain professionals said that <50% of their Sourcing processes are automated.

Industry 4.0 is witnessing Robotic Process Automation (RPA) and AI bots sprint through supplier databases, crafting dynamic RFPs, parsing bids, and optimizing negotiations. Sourcing is transformed from sluggish paper pusher to laser-focused deal shark, devouring cost inefficiencies and showcasing agility.

Automate or evaporate. This approach optimizes the entire breadth of the process – from negotiation strategies to strengthening contract management, driving a shift from cumbersome paper trails to laser-focused sourcing, boosting both efficiency and competitive advantage. In today's dynamic market, automation isn't merely an advantage; it's an imperative.

Understanding strategic sourcing in procurement

Simply put, It is the process between the initial requisition for a product/service and the moment it becomes available for purchase. Putting in more efficiency into this cycle helps an organization to proactively respond to market demands, reduce costs, and navigate turmoil.

Before diving deeper, let us establish the points of difference between the two major approaches in category management: Strategic Sourcing and Tactical/Operational Sourcing.

Tactical Sourcing zeros in on immediate, transactional needs with an eye on short-term gains. In contrast, Strategic Sourcing is the grand orchestrator.

It aligns procurement strategies with broader organizational objectives, emphasizing enduring supplier relationships, risk management, and innovation. For the remainder of this blog, we narrow down our focus on the criticality of Strategic Sourcing processes.

Key Components that Determine the Strategic Sourcing Cycle

1. Forecasting and Categorization

Analyze historical and projected purchasing data: This involves understanding your current spending patterns across raw materials, components, finished goods, and services.

Classify categories based on criticality, complexity, and volume: For example, high-volume, critical components deserve more attention compared to low-volume, non-critical items. This prioritizes sourcing efforts and allocates resources efficiently.

2. Category Strategy

Align your strategic sourcing strategy with organizational goals: Consider cost reduction, innovation, risk mitigation, and sustainability as key parameters. Are you aiming for the lowest price, the highest quality, or a balance between both?

Define your strategic sourcing strategies: Single vs. multi-sourcing, direct vs. indirect sourcing, and global vs. local sourcing based on your strategic goals and risk tolerance. Moreover, advanced techniques like multi-criteria decision analysis (MCDA) and game theory can optimize supplier selection and negotiation.

3. Category Execution

Category Execution involves the operationalization of the chosen category strategy. Integrated data platforms help firms gain visibility into inventory levels, supplier performance metrics, and compliance adherence. Furthermore, AI algorithms can adjust procurement parameters based on changing demand patterns, supplier lead times, and quality metrics, ensuring seamless execution of the strategic sourcing process.

4. Supplier Selection

Develop evaluation criteria specific to your needs, focusing on key metrics like price, quality, delivery times, and risk profile. Weighted scoring models become your trusted advisors, helping you objectively compare suppliers and shortlist the most promising candidates. Don't hesitate to conduct in-depth audits, venturing beyond data to personally assess supplier facilities, production processes, and quality control systems. Remember, trust is the cornerstone of any strong alliance.

5. Negotiation and Contracting

The idea is to look for suppliers who not only offer competitive rates but also possess innovation, technical expertise, and a collaborative spirit. Once terms are agreed upon, formalize a concise contract, outlining responsibilities, pricing structures, risk mitigation strategies, performance guarantees, KPIs and contract renewal terms.

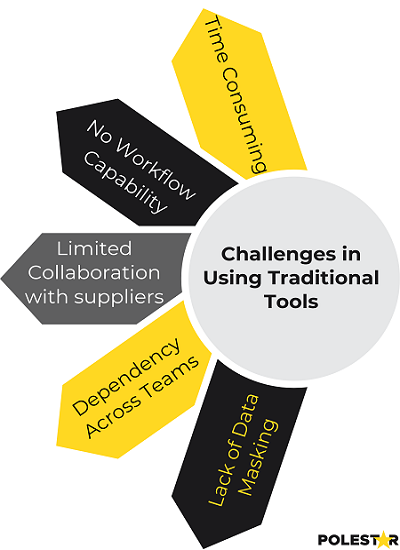

What are the challenges in using traditional sourcing tools?

While the importance of sourcing cycle time optimization is clear, many organizations continue to grapple with challenges when using traditional procurement tools. These tools often lack the advanced capabilities required to streamline the sourcing process efficiently. Here are some of the key challenges associated with traditional tools

Data Analytics providing the edge in Strategic Sourcing

To achieve true efficiency and excellence in the purchasing process, organizations must choose data-driven decision-making to fundamentally reshape the levers of the sourcing process.

Let's explore how data analytics plays a pivotal role in each facet of the purchasing process:

Need Identification: Through historical data analysis and predictive modelling, data analytics enables organizations to forecast demand accurately, initiating the sourcing process proactively. Organizations can eliminate laborious manual tasks, reducing errors, delays, and unnecessary duplications of work. Standardization ensures a simplified, consistent approach, fostering compliance with policies and procedures.

Dynamic Demand Forecasting: Employ cutting-edge predictive analytics on historical data – helps you to predict demand patterns with exceptional accuracy. This capability streamlines the strategic sourcing process – ensuring goods and services are available precisely when needed.

For example, data-driven process mapping and lean principles can highlight areas of opportunity. This approach ensures that the purchasing process remains aligned with business strategies while removing non-value-added steps.

Precision in Supplier Selection: Armed with comprehensive data, organizations can make supplier selection a meticulous, data-driven process. It goes beyond performance metrics; it encompasses financial stability indicators, historical pricing trends, sustainable ways of sourcing and even market intelligence. This precision ensures that selected suppliers aren't just reliable vendors; they're strategic partners in the organization's growth journey.

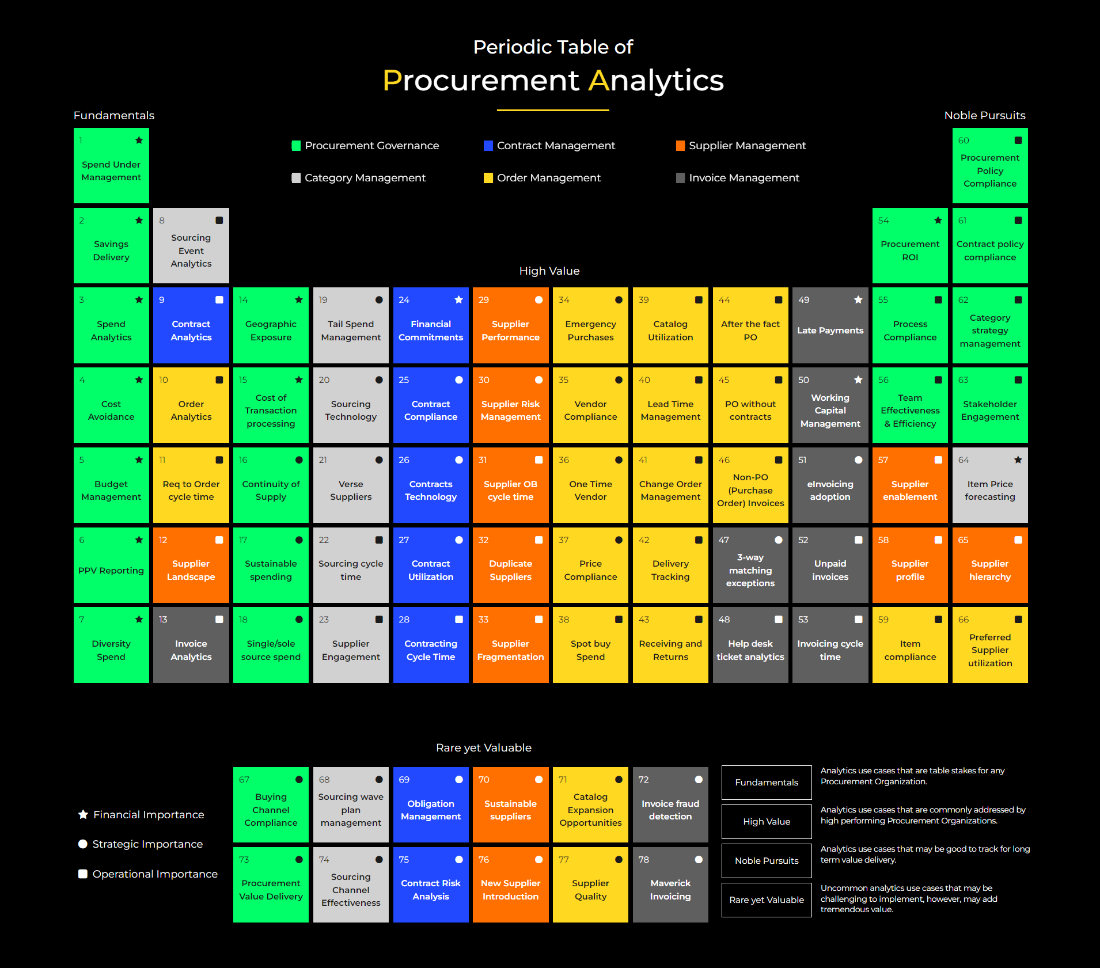

Btw, did you check out the Periodic Table of Procurement KPIs yet?

Material price opportunity: Employing advanced data management, statistical analysis, and forecasting models, businesses can extract meaningful insights from diverse datasets, predicting and reacting to future price trends with precision.

Total Cost of Ownership (TCO): modeling, supplier performance analytics, and the application of game theory principles in negotiation strategies further elevate the technical sophistication of material price optimization. Dynamic pricing models, driven by artificial intelligence, enable real-time adjustments to market fluctuations, while advanced negotiation techniques, such as simulation tools and dynamic pricing algorithms, empower businesses to secure optimal pricing agreements.

Monitor and Improve with Data-Backed KPIs: Data analytics serves as the eyes and ears of the purchasing process, continuously monitoring and improving KPIs. These KPIs, including strategic sourcing cycle time and costs, offer critical insights into process strengths, weaknesses, market dynamics, and opportunities. This helps the users in the implementation of corrective actions, preventive measures, and a culture of continuous improvement.

KPIs must provide actionable insights. For instance, metrics like OTIF (On Time In Full) offer valuable, multifaceted information, revealing supplier reliability, buyer effectiveness, and communication efficiency.

Train and Empower with Sourcing Personnel: Data analytics empowers personnel involved in the purchasing process by equipping them with the skills, knowledge, and competencies required for data-driven decision-making. Training programs, complemented by coaching, mentoring, and recognition, create a cadre of experts capable of leveraging data insights effectively. Empowered individuals can take ownership of the process, make informed decisions, and resolve complex problems.

Risk Mitigation and Compliance Assurance: In today's globalized marketplace, risk management isn't an option; it's a necessity. Data analytics offers a dynamic risk assessment framework that evaluates supplier stability, geopolitical factors, and compliance adherence. This ensures that every supplier relationship is fortified against potential disruptions.

In essence, the role of data analytics in Strategic Sourcing isn't just about optimization; it's about infusing decisions and interactions with data and intelligence – elevating sourcing from a transactional function to a necessity.

Analyzing the future of Strategic Sourcing

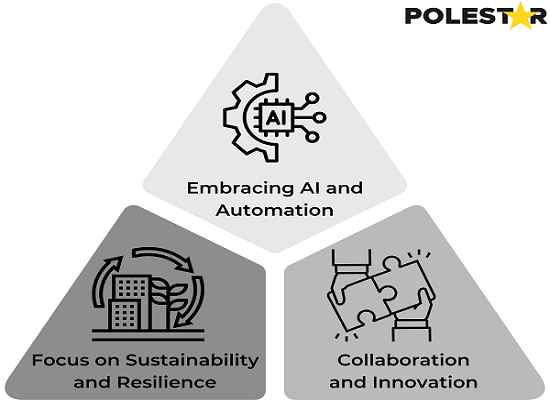

As we see technology disrupt the procurement division, let us explore some of the strategic sourcing best practices for future success:

Embracing AI and Automation: Looking ahead, strategic sourcing in supply chain management could be made more robust with the convergence of advanced analytics with AI and blockchain. This promises to revolutionize the landscape with cutting-edge supplier selection tools. Advanced automation can streamline the complex vendor qualification processeses

Focus on Sustainability and Resilience: Integrating ESG factors into supplier selection will become a cornerstone of responsible business success. Circular economy principles, minimizing waste and maximizing resource utilization, will be embraced as sustainable sourcing strategies. Building agile and geographically diverse supplier networks will be crucial for mitigating geopolitical risks and ensuring business continuity in the face of disruptions.

Collaboration and Innovation: Deep, collaborative partnerships with key suppliers will foster joint development of cutting-edge products and services. Platform-based sourcing will connect buyers and suppliers more efficiently, fostering cross-industry collaboration. The sourcing professional will evolve from a cost-cutter to a strategic value creator, driving innovation and managing risk through expert negotiation and supplier relationships.

Wrapping Up

The strategic sourcing cycle is a key metric in procurement to strengthen operational efficiency. Data analytics arm organizations to optimize each stage of the sourcing cycle, from demand forecasting to supplier performance analysis, ultimately leading to reduced cycle times and improved procurement efficiency.

As technology continues to evolve, embracing data-driven approaches in procurement is no longer an option but a necessity for staying ahead in today's competitive business landscape.