Editor’s Note - In a world where every data tool promises a solution, the real puzzle is fitting them all together seamlessly. Meet the unsung hero: Digital Twins. Think of it as your digital ally in the realm of Sales and Operations Planning (S&OP). Ever wondered how Tesla keeps its cars in top-notch shape or how NASA manages machines in our solar system? Spoiler alert: Digital Twins play a key role. So, if you're navigating the complexities of S&OP, here’s a guide for you where we’ve highlighted how traditional S&OP has evolved with digital twins. Also, explore practical benefits, and envisage a future where your planning is not just efficient but downright innovative.

Landscape of Sales & Operations Planning

Much like a well-coordinated team where every player contributes significantly to achieve a common goal, effective planning relies on the active participation of each department and stakeholder. Sales and Operations are no different.

It was originally designed to encourage collaborative business planning by uniting different functions, sales and operations planning (S&OP) has evolved into a common practice for connecting supply and demand. It ensures a smooth alignment of Sales, Demand, Supply, and Financial Planning.

As per a Bain & Company report, integrating S&OP into the core of the planning process can lead to a substantial enhancement in forecast accuracy, ranging from 20% to 50%

But traditional S&OP strategies operate in silos with an inward-facing approach to their operations having limited agility with limited foresight. Let’s have a look at the missed opportunities.

If you are new to the world of S&OP, here’s a guide for you on “Mastering Sales and Operations Planning”, Explore Now

Why Traditional S&OP misses opportunities to fuel business success?

In some organizations, traditional S&OP processes have transitioned into legacy processes with long cadence and no collaboration. They no longer reap the benefits it intended to provide. Despite attempts with planning software, they often overlook departmental interdependencies. This leads to decisions that neglect crucial indicators, as highlighted by data points such as supply chain leaders struggling with changing customer expectations (70% - Gartner) and missed revenue opportunities (78% - Accenture).

All these shortcomings make leaders consider the need for an evolved S&OP strategy where forecast accuracy and scenario modeling enhancement will help make more informed decisions

Where is the solution then? – enter digital twins

Supply chain modelling has a longstanding history, but in recent times, there has been a surge in the use of the term "supply chain digital twin."

Digital twin technology is taking center stage. This shift provides an opportunity for companies to enhance their planning processes by adopting a more proactive approach. This article will delve into the technical details of why S&OP based on digital twin technology is considered the future.

Evolved sales & operations planning with digital twins

The next generation of S&OP with digital twins offers significant potential to enhance overall business operations and achieve integrated business planning that delivers results. Shall we begin by addressing the foundation and delving into the idea, for sure?

What is Digital Twin?

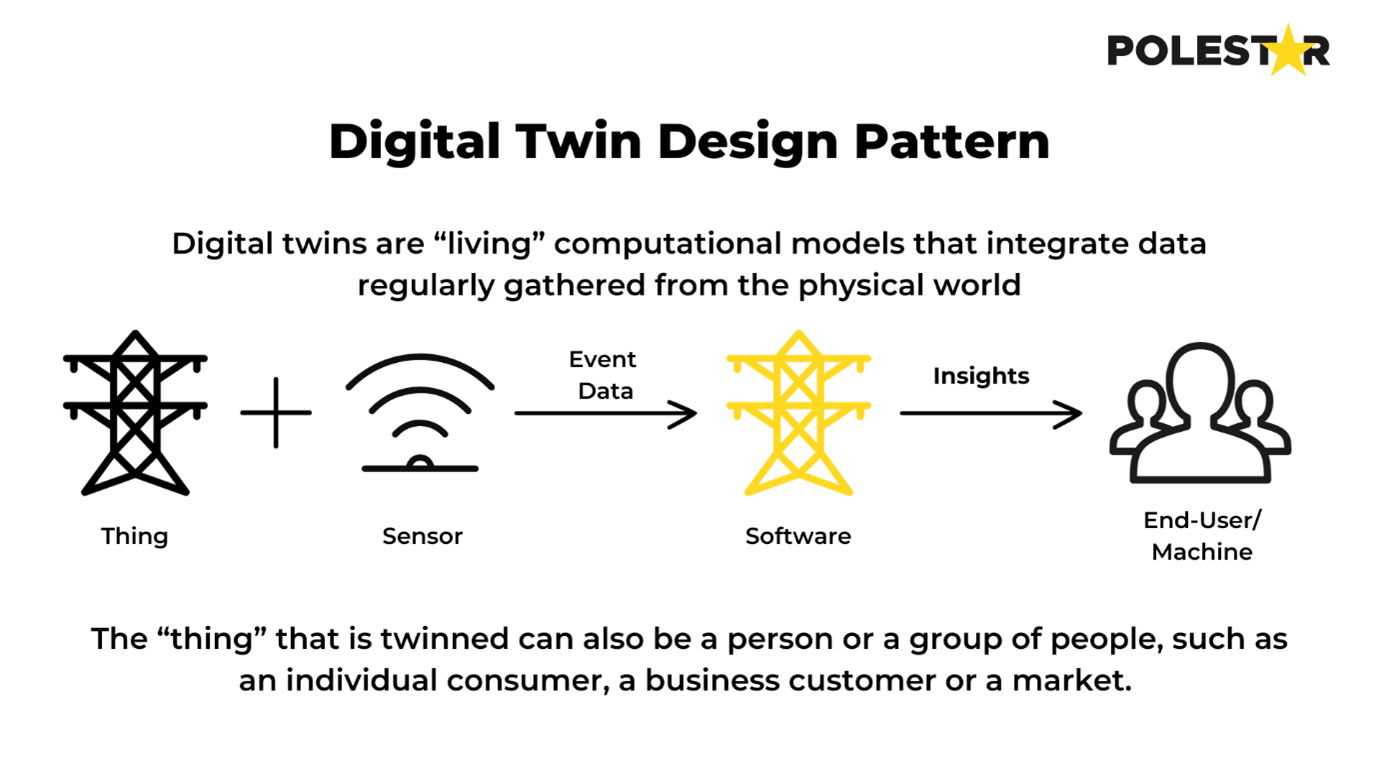

Digital twin technology serves as a virtual duplicate of a physical entity, process, or system, offering an accurate, real-time representation of its functions. This technology collects data from diverse sources, including sensors, Internet of Things (IoT) devices, and machine learning algorithms, to generate a digital counterpart.

Its impact extends across multiple sectors like manufacturing, healthcare, transportation, and energy. Through the simulation of operations, processes, or systems, these virtual models provide in-depth insights into efficiency, performance, and other crucial factors.

For more of your understanding, let’s elaborate on the industry-wise use case.

In essence, digital twin technology holds the potential to revolutionize diverse industries by elevating efficiency, cutting costs, and enhancing safety.

Digital twin in supply chain

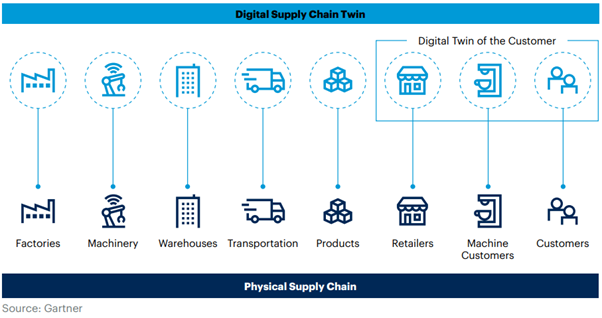

A digital twin of the supply chain is a digital representation of the entire physical supply chain, synchronized with real-world operations to offer visibility and support cohesive end-to-end decision-making. A physical supply chain encompasses various elements, including factories, assets, distribution centers, products, workers, and employees.

The integration of data from individual twins of these supply chain components contributes to the creation of a digital supply chain twin (refer to Figure). Developing a fully advanced digital supply chain twin is a complex task, requiring a distinct digital twin design that incorporates relevant data from the digital twins of individual components within the complete supply chain, such as assets in manufacturing operations, suppliers, products, and customers.

How is it changing?

| Traditional S&OP Traits | Evolved S&OP with Digital Twins |

|---|---|

| Business functions operate in silos when it comes to planning and data | Connected planning leads to better Visibility |

| Approvals and reviews occur in a sequence that spans several weeks | Collaborative approach for End-to-End process management and controlled complexity |

| Limited agility with limited foresight | Fast Risk Assessment and Decision-Making |

Benefits: The Magic of Digital Twins in Supercharging the S&OP Process

Utilizing a digital twin empowers S&OP teams to simulate various decision options, comprehending their cascading effects on the entire business, and considering constraints, uncertainties, and interdependencies. This enhances forecasting, schedule attainment, and the identification of risks and opportunities at all levels.

Moreover, digital twins assist in managing demand and supply imbalances, optimizing finished goods inventory, and early risk identification with recommended mitigation strategies.

Know the power of demand forecasting in S&OP, Explore now

Some of the key criteria that have seen improvement with Digital twin enablement are: -

Beyond Theory: Real World with Impactful Use-Cases by Brands

Tesla creates a digital twin for each car it sells, using sensors to send continuous data to simulations. AI assesses car performance and identifies maintenance needs.

NASA pioneered the use of mirrored systems in the 1960s, a precursor to digital twins, during the Apollo 13 mission. Today, digital twin tech aids NASA in understanding and managing machines in our solar system.

GE employs AI analytics and small robots with visual sensors to detect engine cracks. Advances in technology enable the identification of cracks on turbine blades, even in challenging conditions. Drones equipped with visual sensors inspect corrosion on tall stacks at oil and gas sites.

Bosch compares sensor-driven production data to a digital twin of 100% efficient production lines. This allows quick detection of production deviations and easier identification of trends. Smart production lines result in a 25% output improvement for Bosch's electronic stability program and automatic braking systems.

Ending Words

The future of Sales and Operations Planning (S&OP) lies in adopting digital twin-based approaches. Companies, by harnessing its capabilities, can establish a more precise and proactive planning process. This empowers them to fulfill customer demand while optimizing resources, enhancing efficiency, and minimizing waste. As digital twin technology evolves, it will persist in providing organizations with resilient and effective supply chain planning.

If you’re interested in our services offering Sales & Operations Planning, you can visit our website