Last Updated : 21-September-2023

Manufacturing operations have come a long way since the days of manual processes and guesswork. With the advent of cloud computing and data analytics, manufacturers are now able to make informed decisions and predict potential problems before they even occur. Manufacturing operations are a critical aspect of running a successful business.

They require significant investments in terms of capital, time, and resources. However, as the business grows, the cost of manufacturing operations can become a major burden on the bottom line. Predictive analytics in manufacturing operations involves using data analysis and machine learning techniques to identify patterns and make predictions about future events or outcomes related to manufacturing processes. Manufacturing analytics helps users to improve efficiency, reduce waste, optimize production, and ultimately increase profitability.

In this blog, we will discuss how organizations can leverage manufacturing predictive analytics and determine ways to optimize the cost of their operations.

Predictive analytics is a branch of data science that involves using historical data, machine learning algorithms, and statistical models to identify potential future outcomes. In the manufacturing industry, predictive analytics can help companies improve processes, increase efficiency, and enhance decision-making.

According to a study by Accenture, companies that use predictive analytics in their manufacturing operations can increase their productivity by 6 to 8 percent and reduce their costs by 5 to 10 percent.

This is because predictive analytics allows manufacturers to identify potential problems early on and take action to prevent them from becoming larger and more expensive to resolve.

Key areas where manufacturing predictive analytics can be applied in the businesses

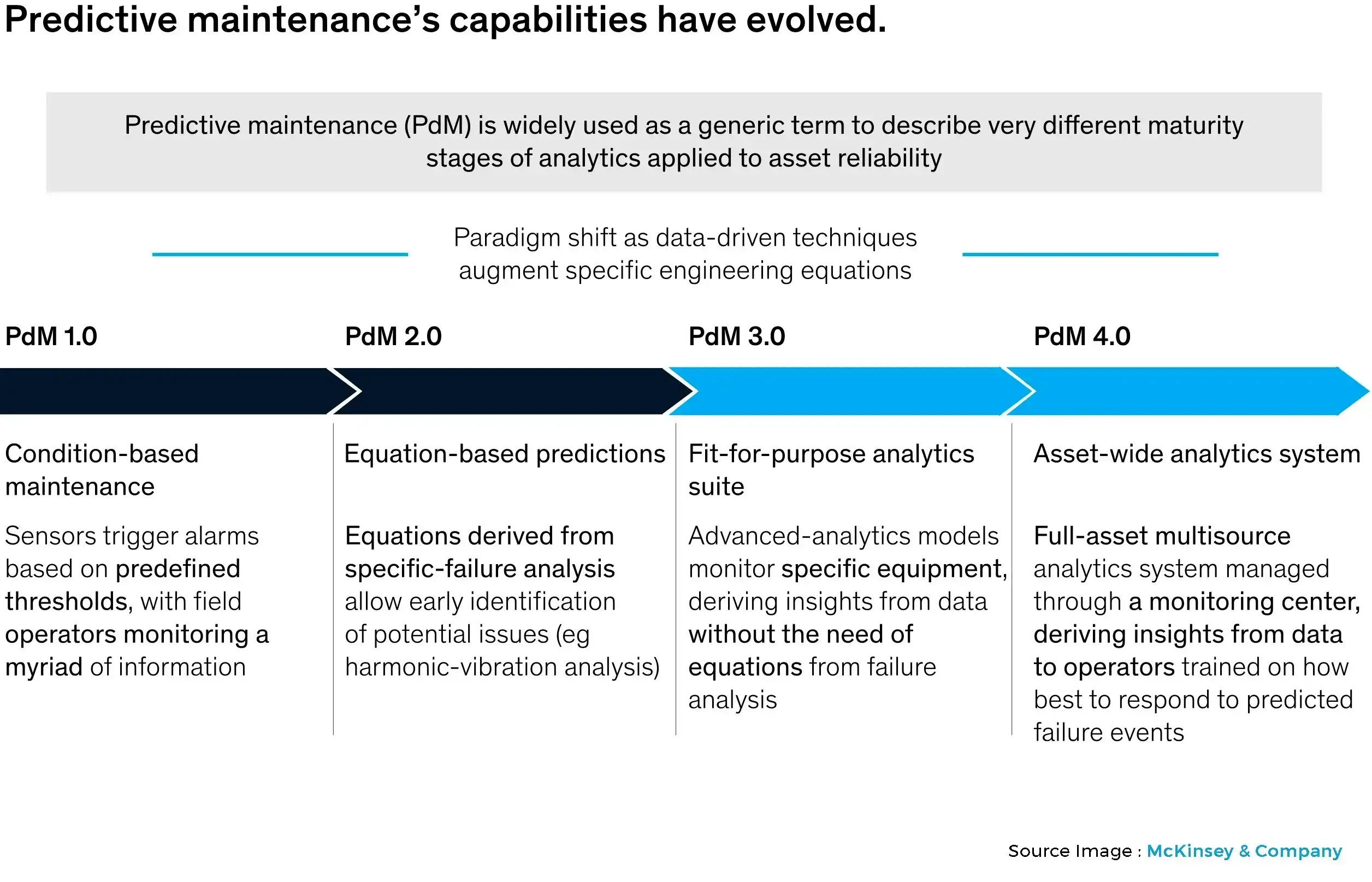

Predictive Maintenance: According to a study by the Mckinsey Global Institute, Predictive maintenance has the potential to reduce maintenance costs by up to 20% and increase equipment reliability by 30%. Predictive maintenance is the use of data analysis and machine learning algorithms to predict when a machine or equipment is likely to fail. This allows manufacturers to schedule maintenance and repairs proactively, reducing downtime and increasing productivity.

Also, a recent study by the Aberdeen Group found that organizations using predictive maintenance saw a 19% decrease in maintenance costs compared to those using traditional maintenance methods.

Quality Control: Predictive analytics can be used to monitor and predict the quality of products during the manufacturing process. By analyzing data from quality control tests, machine sensors, and other sources, manufacturers can identify patterns and anomalies that may indicate a problem with the production line.

For example, a manufacturer of electronic devices can use predictive analytics to detect and prevent defects in the production process, reducing the number of defective products and improving customer satisfaction.

BMW uses data analytics to monitor the quality of its products during the production process. The company collects data from sensors installed in its manufacturing plants and uses it to identify and address quality issues before they become major problems.

Workforce Analytics: In the manufacturing industry, predictive analytics can provide valuable insights into various areas of workforce analytics such as employee turnover, productivity, and skills gap analysis. These insights can help companies make informed decisions and optimize their workforce, leading to improved performance, increased productivity, and reduced costs.

The manufacturing industry has a high rate of employee turnover, with many companies losing skilled workers to competitors. Manufacturing analytics can analyze various factors such as job satisfaction, pay, work-life balance, and employee engagement to identify which employees are most likely to leave. Companies can then proactively address these issues to reduce turnover and retain skilled workers.

Supply Chain Management: Predictive analytics can be used to optimize the supply chain by predicting demand, identifying bottlenecks, and improving inventory management. By analyzing data on sales trends, customer behavior, and market conditions, manufacturers can make informed decisions about production and inventory levels.

For example, a car manufacturer can use predictive analytics to forecast demand for its vehicles, ensuring that it has the right parts and materials on hand to meet customer demand.

Energy Management: Predictive analytics can be used to optimize energy usage in manufacturing facilities. By analyzing data on energy consumption, manufacturers can identify areas where energy is being wasted and implement changes to reduce costs.

For example, Unilever, a global consumer goods company, has set a target to become carbon neutral by 2039. The company is implementing a range of energy management strategies, including investing in renewable energy, improving energy efficiency, and using energy management systems. Unilever has already reduced its carbon emissions by 36% since 2008.

Toyota has implemented a range of energy management strategies in its manufacturing operations, including using energy-efficient equipment, investing in renewable energy, and implementing energy management systems. The company has set a target to reduce its carbon emissions by 90% by 2050.

Process Optimization: Predictive analytics can be used to optimize the manufacturing process by predicting bottlenecks, identifying areas for improvement, and reducing waste. By analyzing data on machine performance, production schedules, and resource utilization, manufacturers can make informed decisions about how to optimize their processes.

For example, a food manufacturer can use predictive analytics to optimize its production line by predicting when certain machines are likely to become congested and adjusting production schedules accordingly.

Role of Data Analytics in Manufacturing Operations

Data analytics has transformed the way the manufacturing industry functions, and it has become an essential part of the manufacturing business. Manufacturers today are leveraging the power of data analytics to improve their operations and gain valuable insights into their production processes. Manufacturers can analyze data from various sources optimize their operations, reduce costs, improve quality, and increase their overall profitability.

One of the most significant ways in which data analytics can benefit manufacturing businesses is by providing real-time insights into production processes. By analyzing data from sensors, cameras, and other sources, manufacturers can gain a deeper understanding of how their equipment and facilities are performing, identify areas for improvement, and take proactive steps to optimize operations.

As technology continues to evolve, let’s see how data analytics will transform the manufacturing industry.

Streamline Your Manufacturing Operations with Data Analytics

Data analytics in manufacturing refers to the use of big data technologies and algorithms to extract valuable insights from data generated during the manufacturing process. With data analytics, manufacturers can monitor, analyze, and optimize every stage of the manufacturing process, from product design to production, delivery and after-sales support.

Supply Chain Data Strategy

A comprehensive data strategy helps businesses identify areas of improvement, reduce risk, and increase efficiency in their supply chain operations. Furthermore, with the rise of e-commerce, businesses are now able to access a large amount of data from different sources, including suppliers, customers, and other stakeholders. Having an effective supply chain strategy in place to manage this data is essential for businesses to stay ahead of the competition.

Polestar Solutions helps you implement a robust Supply Chain Data Strategy and enable increased efficiency, improved customer satisfaction, better visibility into supply chain operations, and informed decision-making with real-time data.

Optimizes production line efficiency

Data analytics provides manufacturers with real-time insights into their production line, allowing them to identify areas of inefficiency and optimize the process. This includes monitoring and analyzing production line performance, production speed, resource utilization, and identifying bottlenecks in the production line. With this information, manufacturers can make informed decisions to improve production efficiency, reduce waste, and increase profitability.

Unable to determine the right data analytics tools to improve your manufacturing processes?

Warehouse optimization

By analyzing data from different aspects of the warehouse operations, such as inventory management, order processing, and distribution, manufacturers can make informed decisions that can help streamline their operations.

For example, by analyzing data on sales and stock levels, manufacturers can determine which products are selling well and which are not, allowing them to adjust their inventory accordingly. This can result in reduced costs and waste, as well as increased sales and customer satisfaction.

Statistics show the effectiveness of data analytics in warehouse optimization. A study by McKinsey & Company found that companies that use data analytics in their operations have seen a 3-5% increase in their productivity levels.

Another study by the International Journal of Advanced Research in Computer Science and Software Engineering found that using data analytics in inventory management can result in a 15-20% reduction in inventory holding costs.

Wrapping Up

In conclusion, predictive analytics has emerged as a powerful tool for manufacturers seeking to improve their operations and optimize their processes. By leveraging machine learning algorithms and real-time data, companies can identify patterns and trends that can inform decision-making and drive operational efficiencies.

Predictive analytics can help manufacturers anticipate maintenance needs, reduce downtime, optimize supply chain management, and even enhance product design. As the manufacturing industry continues to evolve and become more data-driven, predictive analytics will play an increasingly important role in driving innovation and competitiveness.

With the right tools and strategies in place, our experts help you leverage the power of predictive analytics to transform your operations and stay ahead of the competition.