Global supply chains have been buckling under the strain of restrictions imposed by the COVID-19 pandemic but little do organizations know how supply chain analytics can change the game and help them overcome recruitment challenges, substantial fluctuations in goods demand, chip shortages, expensive operational costs, and much more. This storm of challenges has left many organizations with inadequate goods to continue business operations in a usual manner, affecting bottom-line profitability and brand reputation.

It is undeniable that the pandemic has proved to be a real test of the resilience and flexibility of supply chain leaders worldwide. It is forecasted that the global supply chain market will likely experience a CAGR of 11.2% from 2020 to 2027. So, as economies get back to the new normal, the supply chain will be important to securely, swiftly, and safely supply products and services.

What are the risks and challenges faced by supply chain industry?

The supply chain function faces various challenges that contribute to the risks faced by the overall supply chain. Ensuring the quality and availability of data is vital for accurate analysis, mitigating the risk of flawed decision-making due to incomplete or inaccurate information. Integrating data from different systems and sources addresses the risk of fragmented visibility, enabling better coordination and risk management across the supply chain.

Data security and privacy challenges are critical in mitigating the risk of data breaches and unauthorized access, protecting sensitive information throughout the supply chain. Scalability challenges in handling large volumes of data help mitigate the risk of inefficiencies and delays. Effective change management helps mitigate the risk of resistance to adopting data analytics initiatives, promoting a data-driven culture within the supply chain. By addressing biases in data analysis and interpretation, the risk of biased decision-making can be minimized.

Finally, demonstrating the value and return on investment of data analytics efforts helps mitigate the risk of investing in ineffective or inefficient solutions.

Supply chain risks

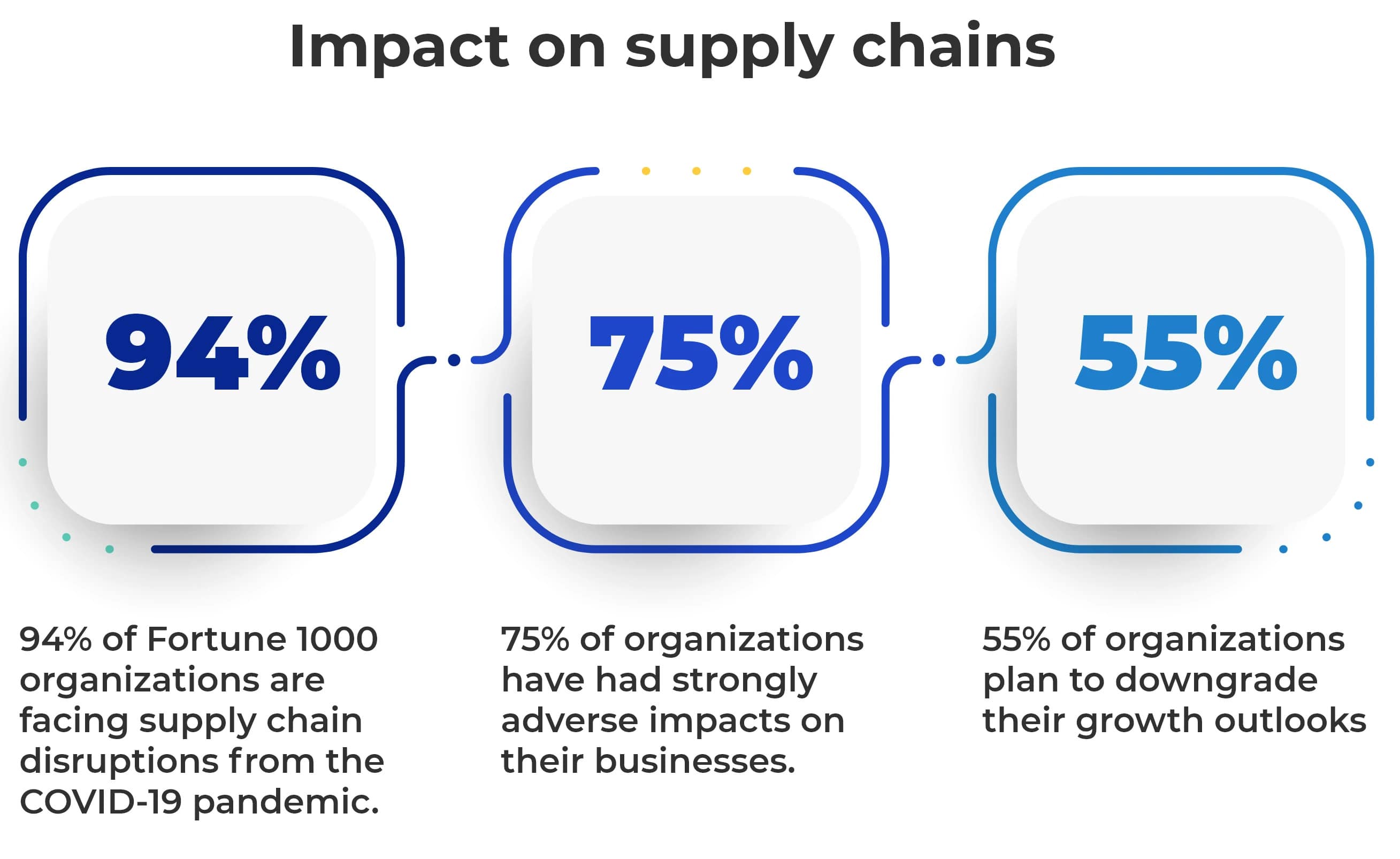

In the wake of the Coronavirus crisis, fundamental shifts in customer behavior, supply chains, and ways to market have hit organizations off balance. To respond to the pandemic disruptions, organizations have faced a sudden push to accelerate the implementation of agile working practices and value chain transformation to navigate uncertainty.

To accelerate the escalation process, organizations require continuous end-to-end assessment, optimization, and monitoring of business operations.

Organizations need to respond rapidly to shape and execute a short-term plan that will mitigate the risks to human health and protect the functioning of global supply chains. Data and analytics capabilities play a crucial role in understanding complexity, forecasting potential disruption, and quickly developing a response.

How to respond to Supply Chain Disruption?

It is imperative for businesses to navigate the operational and financial challenges posed by COVID-19 while rapidly addressing the ever-evolving needs of suppliers and customers. By making strategic decisions on a granular level and capitalizing on supply chain analytics, supply chain leaders can turn disruptions into opportunities.

No matter how turbulent the sea gets, the below-listed vital steps will help supply chain leaders safely steer their corporate ship's supply chain.

#1 Keep a Record of Supplies and Existing Inventory:

Being with assessing what you already have on the table. Consider what you already have as a starting point. How can you utilize what is already available? What do you need to survive the upcoming months, considering any potential demand surges around the holidays?

Gallup research indicates that 60% of consumers were unable to get a product due to shortages. Depending on your industry, you can keep extra goods on hand for times when prices and/or supply are favorable. Even if prices are high, stockpiling extra supplies can bring significant business stability.

Also, by conducting an internal supply chain audit, you can reduce operational costs and enhance competitive advantage where possible during tough economic times.

As machine learning and artificial intelligence continue to make waves in the supply chain, companies like Capgemini use AI to optimize inventory management and reduce waste by integrating SAS solutions into supply chain operations.

#2 Diversify Suppliers:

Diversification may sound simple, but it may be challenging to locate a different manufacturer or distributor depending on the product. Make sure that you have different vendors (both locally and internationally) in your supply chain, and both primary and backup.

It's important to make a list of criteria to consider when choosing an ideal vendor for your business including lead time, pricing, a thorough audit, and a facility tour.

It is wise to select a supplier with strengths aligned with your business goals, wherever possible, effective communication is vital in order to understand how to prioritize one supplier over another. Many business leaders claim that slow response time is the biggest tell-tale sign that a potential supplier will not fit into a business model.

A recent Forbes article reads that multiple-vendor sourcing is the only way to get critical supplies in the event of a disaster that disrupts supply chain operations (think floods or fires).

#3 Maintain a risk exposure map:

You can promptly respond to supply and demand cycles if you have visibility across the whole supply chain. You'll be more adaptable when the global supply chain is disrupted and the logistics stream backs up.

The foundation of any supply chain is the effective planning of sales and operations. Many organizations do not invest in selective technology which often results in inefficient sales cycles.

Those who practice nimble resource allocation and invest in the right technology have been able to benefit from the current inflation cycle.

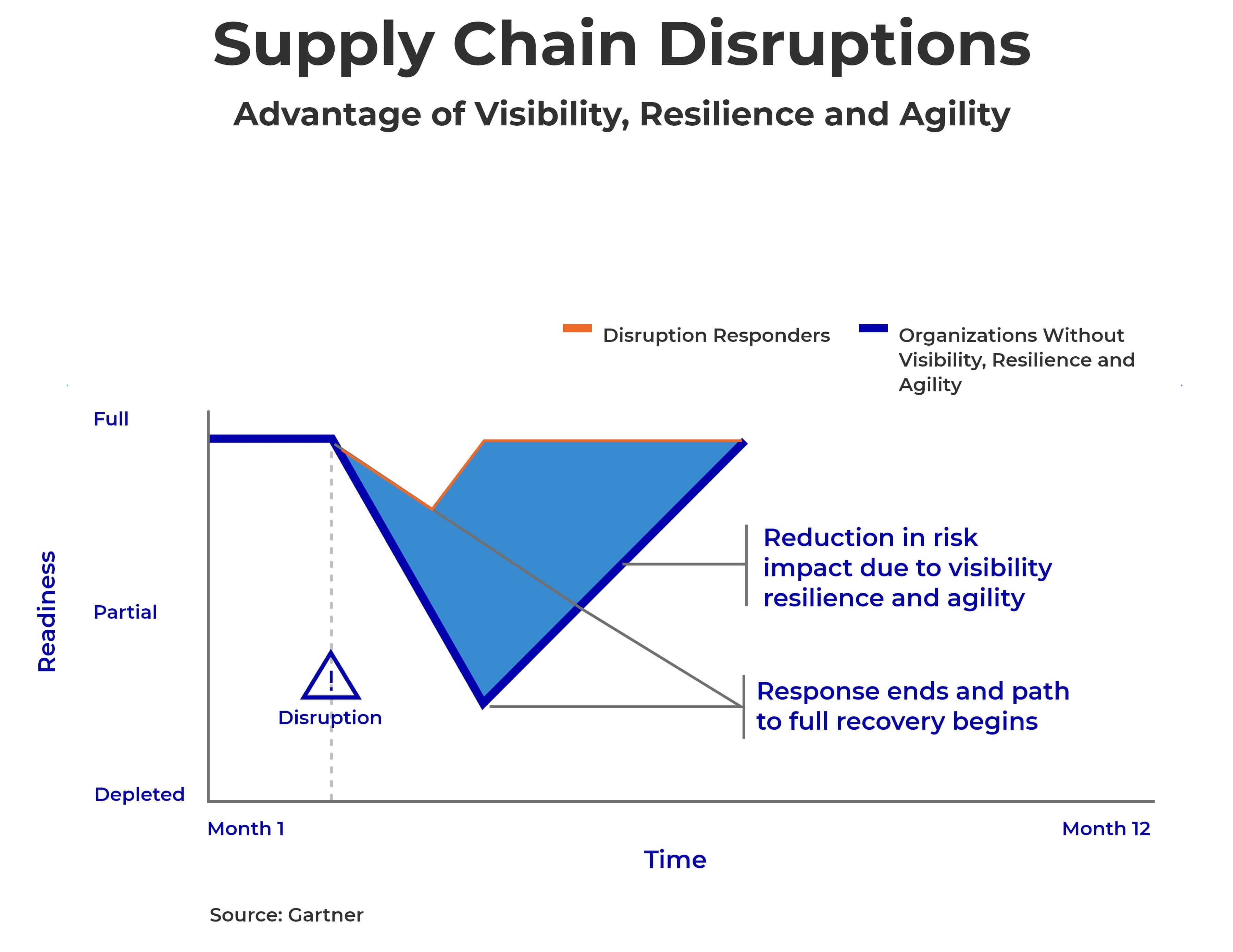

Demand forecasting is followed by production and inventory management. During the COVID-19 crisis, organizations that had invested in visibility software were able to optimize production and inventories, and they are now more adept at handling the current inflation demand cycle.

You can modify the supply chains to reduce risks if you can visually spot supply chain problems in your systems. A supply chain risk map should be maintained for operational and planning purposes.

Companies have been incorporating tools like AI and supply chain analytics to track suppliers’ performance, forecast demand, source more sustainably, optimize production, and ultimately hedge the risk.

#4 Long-term business planning:

Planning and flexibility complement each other while running a small business. Having said that, creating a long-term plan for your organization is an ideal approach to beat the odds when some plans go awry. Long-term strategic planning helps you track your company's progress and identify future possibilities.

A Capgemini director of supply chain transformation claimed that organizations can stay abreast of the industry competition and their peers by ensuring the availability of contingency plans for business-critical processes.

Having formed strong alliances with logistics providers supply chain leaders can better navigate the shortage of containers, truck drivers, etc, and save costs during times of excess demand. To increase the flexibility of their networks, businesses must also intentionally diversify their connections with logistical service providers.

A leading American retailer recently networked with an American ship manager to lease multiple cargo ships for a period of three years. We suppose that when planning the logistics, this retailer looked at its three-year demand curve and wanted to have options for the subsequent years.

Over the coming years, container spot prices might be substantially lower, but this retailer is prepared for possible shortages. Having control over the vessels enables flexibility for retailers in choosing which ports to use.

#5 Digitize your business supply chain:

Digitizing your supply chain will make it simpler for you to plan ahead, identify issues before they turn into big problems, and pivot or launch new lines of business.

For example, TentCraft, a Veteran Owned Small Business (VOSB) expanded the use of digital technology to create a connected ecosystem that helped it align its supply chain and retool manufacturing to build healthcare solutions. AI-powered tools can be used to make smart business decisions based on models of supply and demand patterns.

From increased operational efficiency to flexible support for hybrid and remote work, digitizing your business brings a pool of benefits and navigates supply chain disruptions.

What’s next: Key Priorities for Supply Chain Leaders

Organizations that focus on the key priorities will be able to respond better to extraordinary disruption in the most effective way.

#1. Preserve the extended workforce: Encourage the mental health and physical well-being of supply chain employees while also taking care of their emotional needs.

#2. Rethink your capabilities: Discover ways to repurpose the supply chain for resilience and help societies manage urgent challenges with agility and higher responsiveness.

#3. Secure the supply networks: Strengthen the security of the supply base to proactively address security or compliance issues and reduce legal and financial exposure.

#4. Respond with insights: Leverage digital platforms, analytics for supply chain, and automation capabilities to prioritize customers, geographies, and products and ensure product availability to those who need them most.

#5. Understand and evolve: Learn about root causes and failure modes to determine where to make improvements to supply chains and focus on end-customer outcomes.

#6. Build resilience: Use micro-segmented supply chains and pivot to customer-centricity to create intelligent supply chains with a higher focus on agility, resilience, and social responsibility.

Manage Supply Chain Responsibility and Resilience

The aforementioned key priorities will enable businesses to respond to the extraordinary disruption in the best possible manner, both now and in the years to come.

A McKinsey report claims that 93% of senior supply-chain executives intend to make their supply chains more resilient, flexible, and agile. The main goal is to rebuild the supply chain for the future by enhancing its agility, responsiveness, and resilience at every stage.

However, it is crucial to combine this with a sense of responsibility and purpose in supply chain plans and response protocols. In addition to helping companies overcome COVID-19's challenges, this resilience and responsibility combination will lay the groundwork for future competitive advantage and company expansion.

Wrapping Up

The whole supply chain ecosystem, which consists of manufacturers, shipping and logistics companies, ports, local governments, and retailers, will profit from a solution developed using the above-shared principles. Companies can improve their ability to handle supply chain problems in the future by implementing resilience and redundancy.

Regardless of the multiple technological solutions available, organizations that don't prepare for uncertainty or don't align supply chain effectiveness with efficiency will just not be able to change course rapidly when the black swan event looms in. And in today’s volatile & disruptive business landscape, that isn't an option.

At Polestar Solutions, we provide Anaplan for supply chain planning to improve supply chains for the benefit of customers and the company’s bottom lines. We keep up with the latest trends, research, and insights about supply chain planning, inventory optimization, and demand forecasting to create maximum value for your business.