We are living in a new wave of automation. Machines are already performing many tasks previously done by humans, and the increased use of various innovative technologies such as machine learning and AI means the changes have only begun.

Every day, supply chain executives are tasked with meeting the rising demands of their customers. Whether it is speeding products to market, shifting business strategies to include fulfillment capabilities, implementing new technology, or reducing risk, the end result is always to keep customers happy and loyal. We are already witnessing the trend toward automation begin to play out in supply chain planning processes. The right automation technology in the right place is not a job killer; it's a job changer.

A sea-change in attitude is already developing towards planning. Most organizations are now experiencing a constant need for human intervention in dealing with the flood of data that a typical supply chain analytics produces every day. Companies that embrace a low-touch, more automated approach to planning can make impressive gains in inefficiency.

For instance, internet retailer Wayfair is a mid-market company experiencing rapid growth – more than 50 percent a year. After implementing autonomous supply chain planning, the company slashed the amount of time spent planning to one-sixth of what it was previously.

So, as businesses are increasingly reviewing and revamping their supply chain planning capabilities, through this blog, let's explore how autonomous supply chain planning capability can yield maximum value for CPG organizations.

What is Autonomous supply chain planning?

Autonomous planning is a constant, closed-loop planning approach built on a fully automated technology platform to optimize real-time processes. For large, complex organizations, autonomous planning can help supply chain solutions function more effectively in volatile environments and require less direct human oversight and decision-making. It combines big data and advanced analytics at every step of the supply chain planning process.

How SCM analytics is helping CPG organizations?

The autonomous supply chain planning process leverages advanced technologies such as Artificial intelligence (AI) and Machine learning. It holds up the evaluation of millions of data points and the generation of insights from them. Businesses will better understand current and historical supply and demand to determine the best course of action to keep pace with the customer requests, regardless of market conditions.

Moreover, autonomous planning for the supply chain solutions ensures your organization can accurately forecast how various conditions may affect its operations. For instance, it can forecast what would happen to the CPG supply chain if its operations came to a sudden halt. This allows organizations to plan for worst-case scenarios and limit their impact.

This kind of solution can also provide time and cost savings since companies can utilize autonomous supply chain planning to identify performance glitches in their early stages. Furthermore, businesses can produce reports to trigger supply chain performance over time and find methods to improve CPG supply chain operations and keep the costs associated with them as low as possible.

Our extensive autonomous supply chain solutions for the CPG industry will make your organization agile, transparent, granular, and efficient.

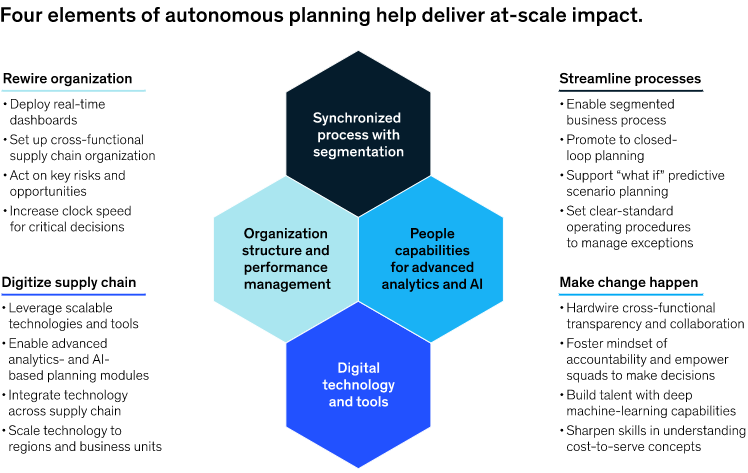

Although it is entirely based on technology, autonomous planning needs more than software and hardware. That's because it necessitates a shift in the way that organizations work based on a set of foundational principles:

- Decreased human involvement by relying on automation to handle most processes, with manual interventions required only to address exceptions and special circumstances.

- Rely on advanced integrated CPG analytics throughout the supply chain, moving beyond standard software functionality for individual processes to curate an explicit link from demand forecasts and orders to the production schedule and plan.

- Evolve from structured planning processes typically slow, reactive, and rigid—to a more fluid approach based on continuous and cross-functional touchpoints that can proactively integrate real-time information.

- Build the organizational capacity to evolve by piloting new use cases, learning from experience, and developing data and analytics capabilities.

As it is so comprehensive, autonomous supply chain planning leads to improved performance in a range of processes across the global supply chain.

- Increased service levels- As organizations better understand and capture the variability of future demand via forecasting, they can predict consumer behaviors more aptly and meet their demand with a higher level of confidence.

- Optimized inventory- Inventory levels can decrease by 10 to 20 percent, often with a corresponding drop in inventory costs, while still meeting required service levels.

- Improved planning efficiency- Automated execution equips enterprises with a robust tool that allows demand planners to shift focus to more complex issues and enhance organizational efficiency.

Four elements to deploy autonomous planning

Where is the consumer packaged goods industry today in terms of adopting this capability?

Just like we've seen successful applications of autonomous systems in aircraft, automotive, and other transport mechanisms, we are seeing it successfully today in consumer goods. Why? Organizations have reached sheer maturity when it comes to connectivity, their capability to acquire precise data close to the source and store it, and the obtainability of machine learning and advanced modeling techniques to learn from this data.

Additionally, flexible compute architectures enable complex models to learn in high-performance cloud computing environments while being deployed at the "edge" resulting in quick system influence with low latency.

We help enterprises implement CPG data analytics solutions to ensure that they can compete and thrive regardless of what the future holds.

Conclusion

Therefore, in the current complex and volatile environment, the consumer packaged goods industry can no longer rely on the traditional supply chain planning processes. Instead, they should look for a clear opportunity to improve financial and operational performance by implementing autonomous planning across the end-to-end supply chain analytics.

We at Polestar Solutions embrace new technologies, where we help enterprises implement autonomous solutions to ensure that they can compete and thrive regardless of what the future holds.