Last Updated : 20-March-2024

Editor's Note: In this insightful blog post, we'll delve into the transformative power of data analytics and automation in the realm of inventory management. As businesses increasingly navigate the complexities of supply chains and inventory control, the integration of automated inventory management systems emerges as a pivotal solution. Through harnessing the capabilities of technology, organizations can streamline operations, optimize stock levels, and enhance overall efficiency. Explore Now!

Globally, the first thing customers do after picking up an item from shelves is to check the "Manufacturing date" and "Best before / Use by" and prefer the latest manufacturing date products to put in a cart. On average, one retail store keeps 3,000 items to over 10.000 items depending on the size of the store. By looking at such a vast number and variety of FMCG organizations, keeping store shelves free of expired food can be a much more tedious task.

2020 was a challenging year for organizations worldwide. Changes in ordering volumes disrupted supply chains, transportation issues have made it so much harder for organizations to operate. However, imagine you could have an automated inventory system. The system will allow you to manage your stock easily, predict the demand, plan for force majeure situations, and even more. The one that will enable your business to operate smoothly. In this article, we will talk about automation in inventory management and wonder if it can work for your business. Let's explore:

How organizations have reacted to the effect of Covid-19

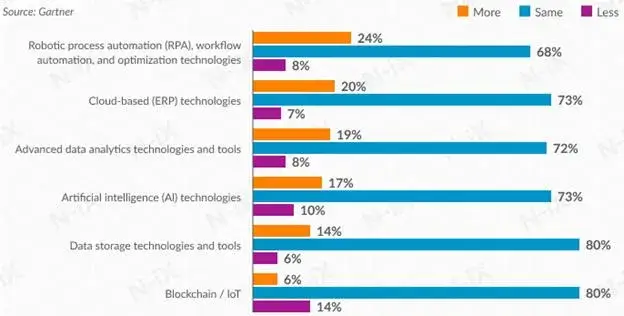

Professionals from a research advisory firm Gartner claim that the Covid19 global financial impact on the economy will swing between $2T and $4.5T. Despite the cutbacks and initial shocks in March and April, many companies are keeping up or even planning to invest more in tech that boosts automation.

Source: Gartner

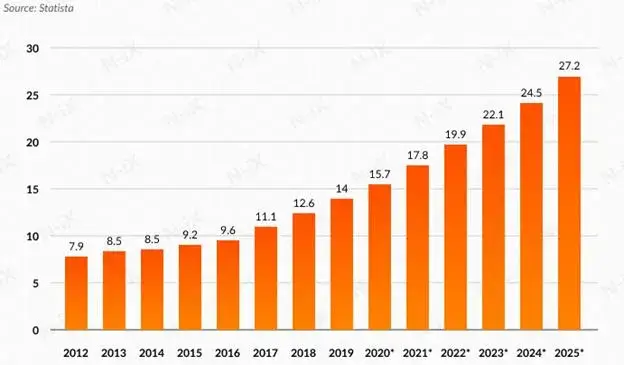

The warehouse and inventory management market were growing steadily before the pandemic. As of the end of 2019, this field was expected to double by 2025. With the worldwide pandemic and an ever-increasing need to reduce human involvement in all the processes, the numbers will grow even more.

Source: Statista

The software market that powers inventory management automation was estimated to reach $5B by 2026.

Source: GMI

Why organizations should adopt analytics and automation in Inventory management

While some organizations invest heavily in automation, many others lag and lose their competitive advantage. Let's navigate through some of the benefits that automation in inventory management brings to leading organizations in the current scenario.

1. Save money and time

Manual labor is expensive, especially when it comes to effect inventory management automation inventory, and warehousing. So organizations often automate inventory management to save a handful of money. A U.S. warehouse spends nearly 65% of the budget on labor, and this figure is increasing by 3% each year. According to research, by adopting radio-frequency identification (RFID) technology alone, organizations can save between $6k and $72k, depending on the size of their inventory.

Source: ABI research

These are the annual costs that any organization can cut down by decreasing inventory-related labor. Additionally, an automated inventory system helps your company save time that otherwise would be spent on manual maintenance of inventory.

2. Increase scalability

Some organizations have experienced a tremendous change in the amount of inventory they required to handle during the pandemic. The secondary reason for inventory management automation is scalability, allowing organizations to adapt to market shifts quickly and change their stocks. It is specifically true for seasonal changes and can assist organizations that highly depend on events such as- Black Friday.

3. Reduce human involvement

The pandemic outbreak has changed the traditional working environments. WHO significantly upgraded safety demands for working systems. If organizations invest in an automated inventory management system, they will involve less personnel and maintain recommended social distancing requirements. And with fewer workers involved, you reduce the chances of human error.

4. Improvement in operation efficiency

With the help of data analytics operations managers can have a real-time view of the operations and a better understanding of the metrics. This helps in getting rid of all the bottlenecks which helps in improving the efficiency of your sales. Big data also enables supply chains to proactively enhance performance when compared to traditional models. Effective inventory management that involves data analytics helps in resolving the following problems which will help in operation efficiency improvement.

5. Increasing customer satisfaction

The real-time data gained with the help of data analytics helps in understanding the main reason behind the sale of a certain product or the reason behind the return of certain products. This helps in making efficient business decisions. Data can also be used to predict seasonal trends, spikes, or depressions in the demand of the customer to make sure that the right level of inventory is maintained at all times to meet the needs of increasing customer demand in seasons.

Gain insight into inventory activities that define crucial strengths and weaknesses with our Data analytics consulting services

Some Practical advantages of analytics and automation in inventory management

Apart from large-scale reasons that make organizations invest in automation of their inventory management, various specific perks that this decision of the companies brings to the table.

Real-time access to data- Knowing the geography of every item, understanding how poorly or well a specific warehouse is stocked, and the capability to generate any report at a given time - these are the things that offer a competitive advantage when it comes to inventory management systems.

Preventing outages and overstock- Apart from adequate storage space, knowing what and when to restock helps companies maintain the right balance in production and delivery.

Integration with existing software- Most organizations have CRM and ERP systems at their disposal, and an automated inventory management system can be easily embedded with the current ecosystem in an organization.

Avoid the risk of overselling- When the person responsible for inventory management knows his inventory well, he can stop any kind of oversell. When an order comes he knows exactly how much is stocked in the warehouse and what amount of order would be safe to accept. Having analytics in inventory Management to handle the whole system, you can surely avoid such situations.

An organized inventory- Analytics can help to maintain a warehouse where everything is organized properly. And it will allow prompt actions when the order comes. And taking less time in delivery only increases happy and loyal customer numbers.

As you can see, analytics and automated inventory management come with numerous advantages. No wonder that organizations around the globe are heavily investing in inventory management software development. So, that brings us to the question- what technological advancements are powering inventory management automation?

4 Analytics and automation Tech Trends in Inventory Management

#1 Wider adoption of data analytics

According to a report published in The Economist titled "The world's most valuable resource is no longer oil, but data". Since then, the craze around data has been growing phenomenally. Organizations gather a humongous amount of data about their clients, processes, turnover, or even market changes. However, only a handful of organizations are utilizing the full potential of data analytics. On the graph below, you can see the new data analysis used by various organizations.

Data analytics assists organizations in several ways, based on the kind of information collated. Automation in inventory management relies on the 4 major types of data analytics:

Descriptive: what is happening with the inventory system and how effective the processes are, and more.

Diagnostic: why specific processes are less effective or are failing.

Predictive: when do the stocks need to be altered and when will the next peak in sales appear.

Prescriptive: How can every step of the process be optimized to reach its full potential.

Adopting data analytics will help the organization improve their processes, manage obsolescence, liquidate excess stock, forecast the demand, classify inventory more effectively, and react accordingly.

#2 Deeper integration of machine learning and AI into business processes

The technology trend is often adopted by larger companies. According to a study, nearly 20% of enterprises have some form of ML embedded in their operations. Additionally, many organizations are experimenting with natural language processing and conversational interfaces.

And while organizations are still catching up with industry leaders, ML algorithms are becoming more and more popular in automating inventory management systems. They assist organizations reduce manual work, optimize costs, enable intelligent decision making, and streamline inventory management.#3 Computer vision

Numerous organizations are successfully adopting this technology, and here's how it can help you optimize inventory management:

Improve stock-taking- For instance, an automated system can trigger current inventory levels in the warehouse. If the stock level is less, it sends an alert to the inventory management replenishment department. Combined with technology and algorithms, an automated purchasing order can be created.

Reduce human errors- Automated systems can cut down the human counting errors via accurate bar-code scanning.

Detecting damaged items- Automated system allows businesses to allocate defective inventory items with greater precision.

Computer vision is a trend here to stay, as it opens numerous possibilities and business opportunities.

#4 Introduction of 5G

Another technological advancement is the fifth generation of wireless technology, which is expected to provide faster download and upload speed. It will also decrease the communication time between the wireless devices. How does this assist in warehouse management automation?

With more devices and sensors relying on wireless technology, speed and continuous coverage are essential. 5G will acknowledge even remote warehouses to be automated completely. Organizations can introduce an enterprise mobility solution, invest in robotics automation, process and gather data in close-to-real-time, and so on. Thus, 5G will help to boost the adoption of all technologies mentioned above.

All these technological trends will change the traditional approach to automation of an inventory management system. However, it is also essential to find a reliable solution provider that will assist in addressing the existing glitches, find the right solution for your case, and successfully implement it.

Conclusion

Given the importance, benefits, and the current situation of inventory management, organizations need solutions that can assist them make the best decisions on when to order inventory, how much to order, etc, so you can meet customer demand and meet sales targets without having stockouts & excess inventory while shortening your lead times.

At Polestar Solutions, we leverage inventory management automation solutions to identify the optimal inventory levels to meet demand with sheer accuracy. In this way, organizations will be able to maximize revenues, reduce holding costs, and increase customer satisfaction like never before. If you would like to chat about this, feel free to book a session with us.